Expansion Joints

Expansion Joints

What are Expansion Joints ?

- There are other terms in use for Expansion Joints such as Expansion Bellows, Flexible Joints and Compensators.

- A typical Expansion Joint is comprised of one or more metal bellows (most commonly stainless steel) or from materials such as rubber, fabric or plastic such as PTFE. While materials such as rubber, plastic and fabric have their limitations, metal is the most versatile of all materials. Metals are suitable for use at high temperatures, have high strength properties and are resistant to corrosion.

- They are designed to safely absorb the dimensional changes of steel pipe systems and ducts. The changes could be heat-induced expansion and contraction, vibrations caused by rotating machinery, pressure deformations, misalignment during installation or building settlements.

- The main element of the Expansion Joints is the bellow. The bellows are made up of a series of convolutions, with the shape of the convolution designed to withstand the internal pressure of the system, but flexible enough to accept axial, lateral and angular deflections.

- Expansion joints are used in piping systems to absorb thermal expansion or terminal movement where the use of expansion loops is undesirable or impractical. Expansion joints are available in many different shapes and materials. Bellow you will find a short description of Metallic, Rubber and Teflon® joints.

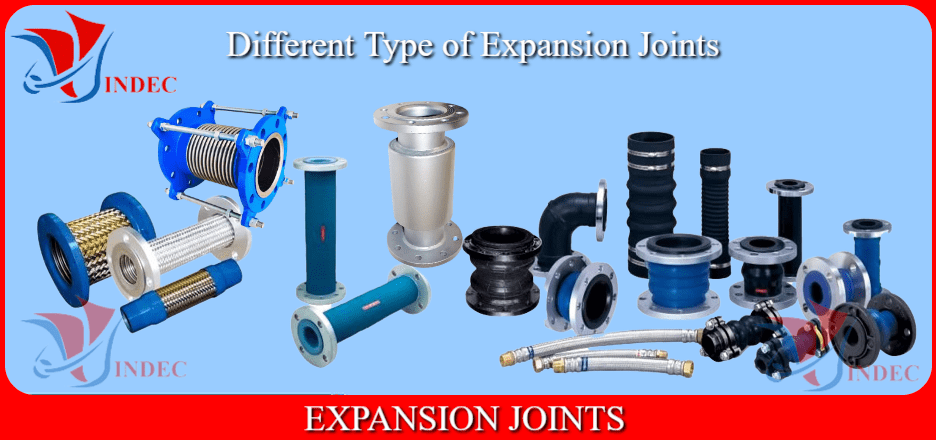

Different Type of Expansion Joints

Rubber Expansion Joints, Metallic Expansion Joints, Stainless Steel Flexible Joints, Stainless Steel Expansion Joints, Bellows Expansion Joints, Fabric Expansion Joints

• Rubber Expansion Joints

• Metallic Expansion Joints

• Stainless Steel Flexible Joints

• Stainless Steel Expansion Joints

• Bellows Expansion Joints

• Fabric Expansion Joints

Why should We use an Expansion Joint ?

- They are considered as very important components of a complete pipe system and are widely used particularly in industries where thermal expansion in pipe systems occur. They also offer the advantage of reducing stresses in pipe systems generated by thermal expansion, and reduce pipe loads at connections to sensitive equipment such as pumps and steam turbines. Taken together this acts to prolong the service life of pipe systems, and reduces the risk of their downtime for additional maintenance and repair.

- Engineers and pipe designers routinely incorporate expansion joints into their pipe systems, as Expansion Joints add flexibility in to the design and reduce costs through removing the complexity of fix points, guides and reduces the overall space requirements for the pipe system.

- Further, they are more effective than alternatives such as pipe bends and pipe loops due to their greater ability to conserve space, their economic efficiency and better performance in absorbing larger movements.

Application of Expansion Joint ?

- They are important components in many industries and are used extensively in among others:

- Energy sector (power plants, nuclear power plants, district heating pipe systems etc.)

- Steel plants

- Petrochemical industry (oil refineries, pumping stations, oil rigs etc.)

- Chemical industries (asphalt manufacturers etc.)

- Process industry (sugar factories etc.)

- Exhaust systems and engines

- Pulp and paper industries

- LNG/LPG tankers, -carriers etc.

- They are often installed near boilers, heat exchangers, pumps, turbines, condensers, engines and in long pipe systems or pipe ducts.

What is Rubber Expansion Joints ?

- Rubber Expansion Joints are a flexible connector fabricated from natural or synthetic elastomers and fabrics with metallic reinforcements designed to provide stress relief in piping systems due to thermal changes.

When flexibility for this movement cannot be designed into the piping system itself, an expansion joint is the ideal solution. Rubber expansion joints compensate for lateral, torsional and angular movements preventing damage and undue downtime of plant operations.

- Rubber expansion joints are used in the transportation of pressurized fluids. As they eliminate the need for coupling gaskets they are widely used in many industrial sectors. They are highly resistant to fatigue and corrosion and have a significant sound-proofing capacity

Technical Rubber Expansion Joints

- Size: DN15 – DN500

- Materials: Neopren, EPDM, NBR, PTFE

- Connections end: Threaded end (NPT, BS...), Flanged end (JIS10K, DIN, BS PN10, PN16, ANSI 150...)

- Temperature range: 0 ~ 160ºC

- Pressure range: 10bar, 16bar

- Origin: Malaysia, Japan, Korea, China, India...

Different Types of Rubber Expansion Joints

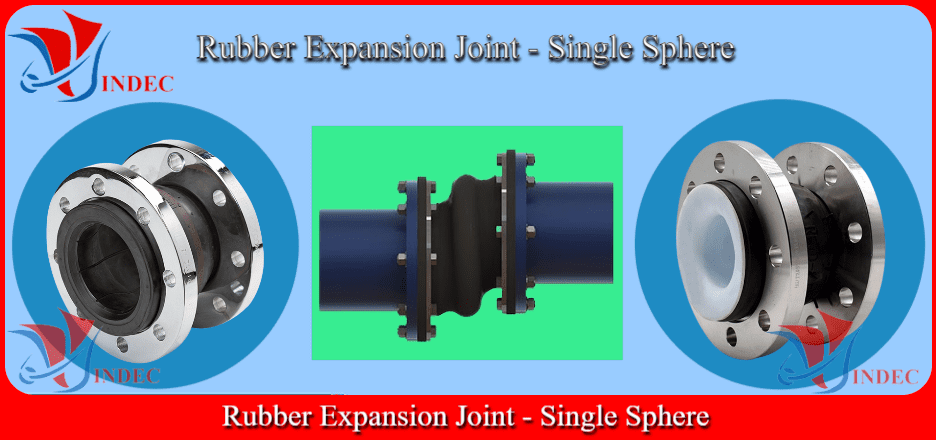

• Rubber Expansion Joint, Single Sphere

- Connection ends: JIS10K, PN10, PN16, ANSI 150 Flanged ends

- Size: 1.1/4" - 16" (DN32 - DN350)

- Material of Rubber: Neoprene, EPDM, NBR, PTFE

Rubber Expansion Joint - Single Sphere

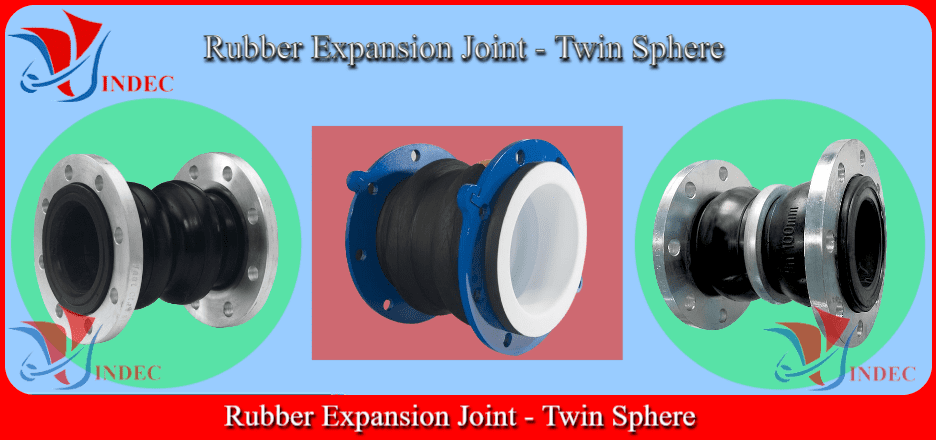

• Rubber Expansion Joint, Twin Sphere

- Connection ends: JIS10K, PN10, PN16, ANSI 150 Flanged ends

- Size: 1.1/4" - 16" (DN32 - DN350)

- Material of Rubber: Neoprene, EPDM, NBR, PTFE

Rubber Expansion Joint - Twin Sphere

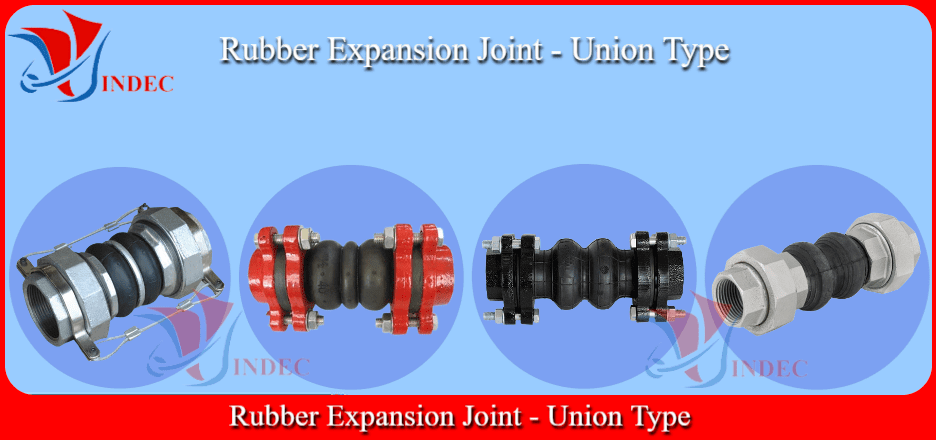

• Expansion Joint, Union

- Connection ends: NPT,BS

- Size: 1/2" - 4" (DN15 - DN10)

- Material of Rubber: Neoprene, EPDM, NBR.

Rubber Expansion Joint - Union Type

Advantages of Rubber Expansion Joint

- Vibration, Reduced Noise, Shock, Corrosion, anti-vibration., Abrasion

- Stresses, Load Stress, Equipment Movement

- Vibration, Pressure Pulsation and Movement in a Piping System

- Increase elasticity and shrinkage for the pipeline system.

- Increase the service life of the pipeline system.

What are Axial Expansion Joints ?

- Axial Expansion Joint absorb expansion laterally, cause by the thermal difference of the media inside the pipeline. The pipeline system is divided into several part and expansion joint are installed along the pipeline according to calculations of expansion.

- Axial Expansion Joints are designed to absorb axial movements (extension and compression in its longitudinal axial direction). The thermal expansion of a straight pipe line section between two fix points can be absorbed by Axial Expansion Joints with a relatively compact build-in length. This offers a simple and cost-efficient solution in terms of movement compensation.

- Axial Expansion Joints can be equipped with all kinds of connectors, such as welding ends or welded or loose (rotatable) flanges.

- Axial Expansion Joints manufacturers to the highest quality standards in the industry. All expansion joints and bellows are 100% tested either by pneumatic, hydraulic or mass spectrometer.

Technical Axial Expansion Joints

- Material of Bellows: Stainless Steel SUS304, SUS316, 316L, 321

- Material of Flanges: Stainless Steel SUS304, SUS316, 316L, 321

- Material of Inner Sleeve: Stainless Steel 304, 316

- Connection types: Flanged end (JIS 10K, DIN PN16, Ansi Class 150..., Butt Weld...etc

- Working Pressure: 10kgf/cm2, 16kgf/cm2, 25kgf/cm2, 40kgf/cm2...

- Working Temperature: -80 upto +550 °C

Different Type Axial Expansion Joints

There are 2 options for this series: Standard axial expansion joints and Axial expansion joints with tie rod.

• Axial Expansion Joints Loose Flanges

• Axial Expansion Joints Welded Flanges

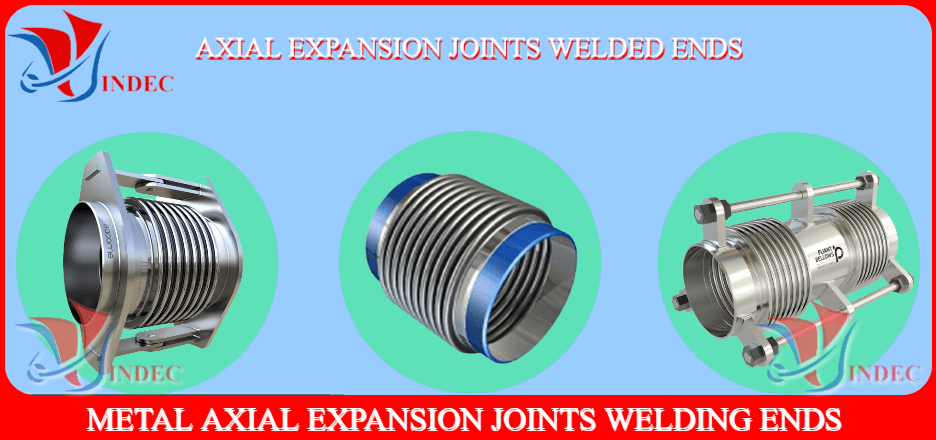

• Axial Expansion Joints Welded Ends

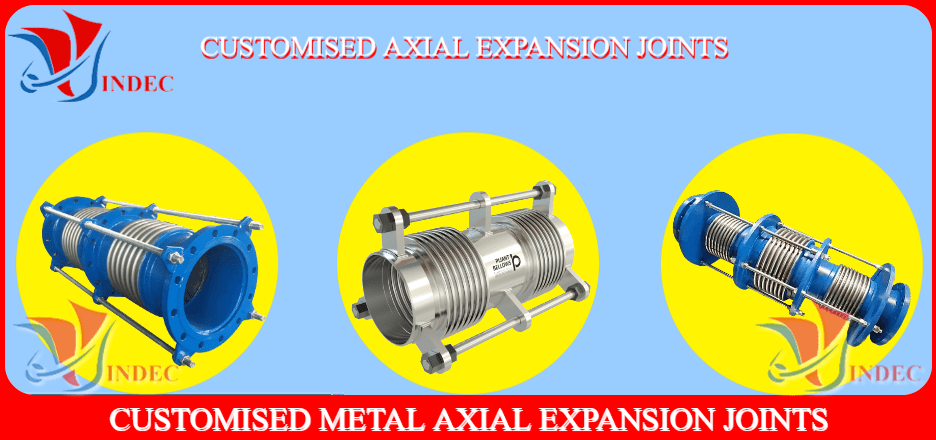

• Customised Axial Expansion Joints

Application of Flexible Metal Joints

- Hot and cold water systems Steam and gas media related systems Oil transporting lines Pressured systems Pumps, motors, machines

- For transferring all type of flow media Natural Gas Steam HVAC.

- Applications LNG and cryogenic.

- Applications Chemical and petrochemical Marine.

- Application Food and Beverage.

What is Stainless Steel Flexible Joints

- Flexible Stainless Steel Hose are high resistant to temperature and pressure, easy to install because of flexible design and have a longer life time because of its resistance to corrosion. Braided metal hose is being used for connection where there is a high.

- Flexible Stainless Steel Hose manufacturers to the highest quality standards in the industry. All expansion joints and bellows are 100% tested either by pneumatic, hydraulic or mass spectrometers.

- Flexible Stainless Steel Hose can be ordered according to customized requirements. All parts such as: bellow, braid, fitting are customizable.

Technical Flexible Metal Joints

- Material of Metal Hose: Stainless Steel AISI321(standard), SUS304, SUS316, AISI 316L

- Braiding of Metal Hose: Stainless Steel AISI 304L, AISI316L, SUS304, SUS316

- Fitting of Metal Hose: Carbon Steel, Stainless Steel ( Others on request)

- Connection types: Flanged end (JIS10K, PN16, Ansi Class 150..., Male, Female, Weld...etc

- Working Pressure: 10kgf/cm2, 16kgf/cm2, 25kgf/cm2, 40kgf/cm2...

- Working Temperature: -196 upto +550 °C

Different Type Flexible Metal Joints

• Flexible Metal Joint Flanged Ends

• Flexible Metal Joint Threaded Ends

- Female swivel and Male Nipple

• Flexible Metal Joint Welding Ends

• Flexible Metal Joint Quick Coupling

Application of Flexible Metal Joints

- For transferring all type of flow media Natural Gas Steam HVAC.

- Applications LNG and cryogenic.

- Applications Chemical and petrochemical Marine.

- Application Food and Beverage.

External Pressurized Expansion Joints

- Metallic External Pressurized Expansion Joints are installed in pipe work and duct systems to prevent damage caused by thermal growth, vibration, pressure thrust and other mechanical forces.

- External Pressurized Expansion Joint is a wide range of metallic bellows designs in a variety of materials. Options range from the simplest convoluted bellows used in petroleum refineries. Materials include all types of stainless steels and high grade nickel alloy steels.

- External Pressurized Expansion Joint External pressurized expansion joints are being used as an alternative for axial type of expansion joints, which movement capability is limited. It is preferred to use for long and straight pipeline in order to reduce the number of expansion joints requirements. It is also easy to cover with any insulation material and it is designed to absorb both lateral and vertical movements.

Technical External Pressurized Expansion Joints

- Material of Metal Hose: Stainless Steel AISI321(standard), SUS304, SUS316, AISI 316L

- Material of Bellows : Stainless Steel AISI 304L, AISI316L, SUS304, SUS316

- Connection types: Flanged end (JIS10K, PN16, Ansi Class 150..., Male, Female, Weld...etc

- Expansion movement (mm): -20/+10; -40/+20; -80 /+40

- Working Pressure: 10kgf/cm2, 16kgf/cm2, 25kgf/cm2, 40kgf/cm2...

- Working Temperature: -80 upto +427 °C

Different Type External Pressurized Expansion Joints

- There are two options for this series: Single Expansion and Dual Expansion.

• External Pressurized Dual Expansion Joints

• External Pressurized Single Expansion Joints

• External Pressurized Expansion Joint Threads

- Female swivel and Male Nipple

• External Pressurized Expansion Joints Flanges

Application of External Pressurized Expansion Joints

- For transferring all type of flow media Natural Gas Steam HVAC.

- Applications LNG and cryogenic.

- Applications Chemical and petrochemical Marine.

- Application Food and Beverage.

- Application: HVAC Piping Lines, Geothermal, Facilities, Thermal Oil Lines, Steam Processing Pipelines, Industrial Cooling Systems, Power generation & Energy plants, Industrial Process & Applications.

Why Should We Use External Pressurized Expansion Joints

Any pipe connecting two points is subjected to numerous types of action which result in stresses on the pipe. Some of the causes of these stresses are..

- Internal or external pressure at working temperature

- Weight of the pipe it self and the parts supported on it

- Movement imposed on pipe sections by external restraints

- Thermal expansion