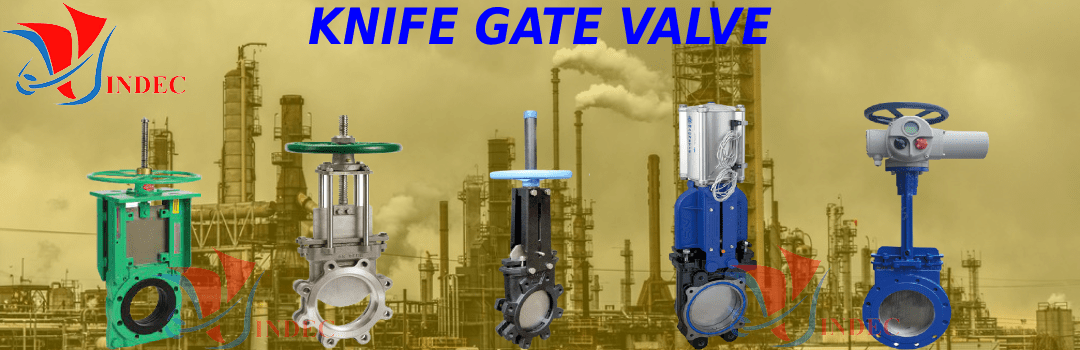

Knife Gate Valves

What is A Knife Gate Valve ?

- Rising stem knife gate valve adopts an integrated valve body casting process. The u-rubber seal lined with side grooves in the valve body is tightly sealed to the edge of the gate to make the valve reach zero leakage standards. This series of knife gate valves have a lightweight structure and sealing performance. Easy to open and close, easy to operate, no groove at the bottom of the valve body, the valve does not block the slag and has full diameter flow. This series of slurry valves are widely used in many fields such as urban sewage treatment, power plants, paper making chemicals, tap water systems, mine slag drainage, etc., and have a very wide range of applications and development prospects.

Technical Knife Gate Valve

- Size: 2”~48”

- Pressure Rating:0.6MPa、1.0MPa、1.6MPa、150Lb

- Material:Carbon steel stainless steel

- Design Standard: JB/T8691-1998,DIN3352

- Inspection Standard:MSS SP-81,DIN3230

- Application medium:water, oil, powder

- Application Temperature:-38-+425℃

- Applied projects:Coal mine/mud/sewage/tap water/ etc

Structure of Knife Gate Valve

- Body of knife gate valve : Cast iron, Ductile iron, Cast steel, Stainless steel...

- Actuator of knife gate valve : Handle, Pneumatic actuated, Electric actuated

- Stem of knife gate valve : Stainless steel

- Dics of knife gate valve: Stainless steel

- Gasket and Oring: EPDM, NBR, PTFE

Operation of Knife Gate Valve

- Nguyên lý hoạt động của van dao dựa trên nguyên lý trục van xoay quanh bạc trục. khi ta vận hành van bằng cách chuyển động bộ phận điều khiển được chuyển hóa thành chuyển động tịnh tiến giúp đĩa van nâng lên hạ xuống để đóng mở dòng chảy trong hệ thống. Quy trình đóng mở van được thực hiện theo cách quay vô lăng, quay vô lăng ngược chiều kim đồng hồ thì van được mở ra và ngược lại quay theo chiều kim đông hồ van được đóng lại.

Nguyên Lý Hoạt Động Van Dao

__________________________________________

Types of Knife Gate Valves

- Van Dao Tay Quay

Van dao tay quay hoạt động dựa trên nguyên lý trục van xoay quanh bạc trục, chuyển động tròn xoay được chuyển hóa thành chuyển động tịnh tiến giúp đĩa van nâng lên hạ xuống để đóng mở dòng chảy trong hệ thống.

- Van Dao Điều Khiển Điện

Van dao điều khiển điện trục của van được liên kết với mô tơ qua hệ thống bánh răng chuyển động tịnh tiến biến đổi nhiệt năng thành cơ năng. Khi cấp điện vào mô tơ, mô tơ quay chuyển động bánh răng quay được gắn với trục của van chuyển động nâng đĩa van lên hoặc hạ xuống để đóng mở van.

- Van Dao Điều Khiển Khí Nén

Van dao điều khiển khí nén khi cấp khí vào bộ điều khiển xy lanh, dưới tác động của lực nén khi cấp vào buồng xy lanh piston sẽ di chuyển để đẩy cần xy lanh lên hoặc xuống. xy lanh được kết nối với cánh van nên khi piston được nén lên xuống trong buồng thì xy lanh cũng được kéo lên xuống và đông thời cánh van cũng được kéo lên xuống.

- Van Dao Gang

Van dao gang là loại van thông dụng và được lựa chọn phổ biến, với giá thành rẻ hơn các loại van dao khác. Van được làm từ gang, sơn phủ bên ngoài lớp sơn Epoxy chống rỉ giúp van được bền bỉ hơn với môi trường.

- Van Dao Thép

Van dao thép được chế tạo từ thép chuyên dụng, van được sử dụng trong các ứng dụng có nhiệt độ và áp lực cao.

- Van Dao Inox

Van cửa dao Inox là van được chế tạo từ inox, với các đặc tính của inox như chịu áp suất cao, nhiệt cao, hóa chất, chống ăn mòn tốt... để chế tạo ra van có giá cao hơn từ các vật liệu khác.

Key Features of Knife Gate Valves

- Simple finish, easy operation and maintenance, high altitude

- When fully open, do not obstruct the flow

- Vales activity by all the two height to allow on the top of two

- Use in the special environment environment

- Withstand high temperature and pressure

- Diversity of species

- Compact, sturdy design, easy maintenance binding

- Not to select the current lines

Application of Knife Gate Valves

- Knife valves are selected to be used mainly in manufacturing plants, hydroelectric power plants, mining, water treatment, chemical industries... suitable for opening and closing water supply and drainage systems, systems Conduction system for dense substances such as mud, sand ....

Lựa Chọn Van Dao

- Body of Knife gate valve: Inox 304, inox 316, inox 201, Thép, Gang

- Connection of Knife gate valve: Nối kẹp, Lắp bích tiêu chuẩn: JIS, BS, DIN, ANSI

- Size of Knife gate valve: DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300, DN350, DN400, DN450, DN500…

- Pressure range of Knife gate valve: 10kgf/cm2, 16kgf/cm2

- Temperature range range of Knife gate valve: 220 độ C

- Actuator :Lever handle, pneumatic actuated, Electric actuated

- Typea of of Knife gate valve : Van dao gang, Van dao thép, van dao inox

- Brands: Van dao King gate, Van dao Joeun, Van dao Arita, Van dao Kitz, Van dao Hitachi

- Origin: Trung Quốc, Đài Loan, Nhật Bản, Malaysia, Hàn Quốc

What is A Pneumatic Actuated Knife Valve

- What is a pneumatic Actuated knife valve? It is also known as pneumatic control shovel valve, English name is Pneumatic Knife Gate Valves / knife gate valve pneumatic actuator or knife gate valve pneumatic cylinder, is a device fitted with a pneumatic actuator, connecting the shaft to the body. of the knife valve, the vane is an iron metal that can go up and down completely out of the way of the fluid, single and vertical. The shaft is floating with pressure up to PN16, PN25.

Structure of Pneumatic Actuated Knife Valve

• Mechanical Valve:

The mechanical knife input part is made of steel, Body and Disc ( stainless steel, cast iron, Cast steel) . The mechanical valve part includes the following parts:

- Valve body: made of stainless steel 304, stainless steel 316, cast iron, steel

- Valve disc: The valve disc or blade will normally be made of stainless steel or steel.

- Valve shaft: The mechanical knife valve shaft is made of stainless steel or stainless steel with high hardness

- Sealing gasket: Pneumatic knife valve has 2 types of sealing: Teflon sealing and steel sealing. Steel gasket can withstand extreme temperature and pressure.

- Control part: normally the valve is controlled by compressed air or by handwheel. In hydroelectric and thermal power plants, the valve is usually controlled by electricity.

• Actuator of valve: This is the part that controls the opening and closing of the pneumatic knife valve with 7 main parts:

- Piston rod

- Mounting

- Cylinder

- Piston

- O-ring

- Rod-end port

- Cap-and port

Operation of Knife Gate Valve

When we supply compressed air to the pneumatic cylinder, the gears in the cylinder rotate to push the valve shaft according to the up and down mechanism, the valve shaft will be connected to the blade. When compressed air is supplied to the upper port, the compressed air will be compressed. will push the valve shaft down, the blade attached to the valve shaft will go down and seal the flow, creating a valve closing mechanism. Conversely, when compressed air is supplied to the lower port, the compressed air will push the valve shaft up, pull the blade up, open the flow then create the valve opening mechanism. In addition, if the valve is connected to a linear controller, it can be opened and closed at an angle from 4 - 20mA.

Advantages / Defect Pneumatic Operated Knife Valve

- The valve opens and closes quickly, the installation space is narrow, the space in the valve line of the pipe is quite narrow

- The pneumatic knife valve is sealed with a metal disc so it can cut other solid objects.

- Used for solid, sharp, viscous fluids

- The valve blade moves up and down, so the fluid pressure does not affect the opening and closing of the valve.

- When opening the valve, the valve blade retracts all the way up, so the valve disc does not block the flow of fluid through.

Application of Pneumatic Operated Knife Valve

- Valves are widely used in systems of cement plants, batching plants

- Valves are widely used in sludge treatment systems

- Used in stone factories

- Used in industrial mines

- Widely used in hydroelectric and thermal power plants

- Used a lot in paper mills

- Application in sugar mills

- Application in flour mills

- Used in plastic factories

- Used in wood factories

- Widely used in tanks, tanks,...

- The main function of the pneumatic knife valve is to automatically operate and discharge water, residue, liquid, chemicals, coal, sugar and is specialized for the paper industry.

What is A Cast Steel Knife Gate Valve ?

- What is a steel knife valve? steel knife valve is a knife valve product made from 100% entirely from WCB steel metal. WCB steel material is a material that can withstand high temperatures, withstand high pressure and especially it is used for water systems, sea water, gasoline, oil and steam.

- WCB steel knife valve opens and closes thanks to the steering wheel handwheel system, in addition, it can be opened and closed by electric control and pneumatic control. Steel knife valve is made of thin flat disc and body, valve disc. and the disc lifts up and down according to the axis of the valve. With the mechanism of lifting and lowering, it is suitable for systems of industry, food, pharmaceuticals, animal feed, building materials.

- Steel knife valves are made from many different sizes, temperatures, pressures, connection types, functions and origins creating different products.

Technical Cast Steel Knife Gate Valve

- Size of WCB Steel knife valves: DN50-DN1000

- Body of WCB Steel knife valves: thép WCB

- Stem of WCB Steel knife valves : thép WCB

- Dics of WCB Steel knife valves: Inox304, thép WCB

- Lever handle : Gang, thép

- Pressure range: 10,16,25 bar

- Temperature range: 450 độ C

- Connection ends: Flanged ends

- Standard : JIS, DIN, ANSI, BS

- Media of WCB Steel knife valves : Nước, xăng, dầu, hột, hạt

- Origin: China,Korea,Japan,Taiwan

Application of Cast Steel Knife Gate Valve

WCB Steel knife valves are used in many silo systems, conveying hard granular materials, cohesive powders, specific systems such as:

- WCB Steel knife valve is used for pulp industry, cement silo, stone powder silo system.

- WCB Steel knife valve is used for coffee production machines, tapioca starch factories

- WCB Steel knife valve is also used for hydroelectric power plants, thermal power plants, wastewater treatment plants, building material silo systems.

- When deciding to buy a steel knife valve, it is necessary to note the parameters of the system, the size of the pipe, what is the temperature, pressure, connection type, material and origin. Choosing the right quality steel knife valve for the system helps to save costs, increase service life, operational efficiency, and safety for users.

Advantages / Disadvantage Steel Knife Gate Valve

• Advantages of Steel Knife Valve

- WCB steel knife valve withstands very high heat up to 450 degrees

- Steel knife valve withstands pressure up to 16 bar

- Has the advantage of opening and closing without causing vibration, no jamming of materials, no jamming of the valve

- WCB Steel knife valve can be installed in many terrains on high, underground legs, installed in many environments, toxic environments

- Can be installed in a variety of ways such as standing, tilting, diagonal

- Various sizes

• Disadvantage of Steel Knife Valve

- WCB Steel knife valve is not suitable for the environment of corrosive concentrated chemicals

- And the WCB steel knife valve is not the type of valve used to regulate the large and small flow of the flow

What ís A Electric Operated Knife Gate Valve

- What is an electrically controlled knife valve or an electrically controlled shovel valve, they are internationally known as Electric Actuator Knife Gate Valve / Electrically Operated Knife Gate Valve. It is an industrial device used to regulate the flow of fluids through pipes.

- The valve works thanks to the blade part connected to the electric motor (electric controller) to help the valve open and close the flow of substances such as wastewater, clean water, mud, coal, cement, ...

Technical Electric Operated Knife Valve

- Size: từ DN 50 đến DN 1200

- Materials of body: Gang,gang dẻo,inox , thép,..

- Chất liệu bộ điện: hợp kim nhôm,nhựa,inox,...

- Gasket: PTFE,EPDM

- Electric motor : 220V,380V ( 1 pha, 3 pha)

- Áp lực làm việc: PN10,PN16

- Temperature range: -5 độ C đến 200 độ C

- Tiêu chuẩn van: I67 chống ẩm

- Connection ends : Flanged ends ( wafer,lug)

- Media: nước sạch,thải,chất đặc sệt,...

- App;ication: xử lý nước,than,bùn, xi măng,...

- Origin : Taiwan,Korea , Asian , Châu Âu,...

Structure of Electric Operated Knife Valve

• Knife Gate Valve

- Knife gate valve is a valve that uses a blade to open and close directly to help prevent or let the flow of fluids through.

- The valve is composed of the following parts: blade, flange body, sealing gasket, connecting shaft and bolts and screws.

- Knife gate valve can connect with many controllers: electric controller, pneumatic controller, handwheel, ..

• Actuator of Electric Operated Knife Valve

- Unlike the electric motor of the ball valve and butterfly valve, which rotates at an angle of 90 degrees, the motor of the electric knife valve is reciprocating up and down, converting thermal energy into mechanical energy to help the valve operate.

- The electric control unit of the knife valve includes: an electric motor, reciprocating gears using voltages of 240V and 380V , designed according to I67 standard, moisture-proof, anti-electrostatic and connected to the knife valve part.

Operation of Electric Operated Knife Valve

- The electric actuated knife valve will operate according to the principle of reciprocating opening and closing. When the motor is energized, the gears will move up or down and pull the shaft attached to the blade to move, creating valve opening and closing phenomenon. The knife valve part will be connected with flanges to piping systems that can withstand high pressure and temperature of about 100 degrees Celsius.

Application of Electric Operated Knife Valve

With its modern design and convenience, the electric knife valve is widely used in many different industries and fields:

- Application in manufacturing industry: pulp, suction sand, mud, coal, ...

- Application in systems to handle solid, viscous liquids, ...

- Application in wastewater treatment system, clean water, sea water, multi-use water, ..

- Application in liquid and chemical plants such as dilute acids, gasoline, oil, ...

- In addition, it is also used in hydroelectric power plants, thermal power plants, ...

Advantages / Disadvantage Electric Operated Knife Valve

The outstanding advantages of electric knife valve:

- Knife valve has a blade, so it is good to use in dense environments

- Electric knife valve has a simple structure to save materials for valve installation and reduce weight

- The valve occupies less space which is convenient for system control and maintenance

- Flange mounting valve prevents leakage

- Made of stainless steel, anti-corrosion and durable

- Can be used in solid and liquid environments, chemicals such as petroleum, mud, sand, ...

- Fully automatic controlled by electric controller

- There is a valve that will have a handwheel in case of power failure

- Resistant to high temperature and high pressure

- Valves can be fitted with additional components such as pressure gauges, temperature gauges, signal sets, ..

- Stable opening and closing, suitable for many systems

What is A Stainless Steel Knife Gate Valve ?

- Stainless steel knife valve, also known as stainless steel knife gate valve, English name is Stainless steel knife valve. Stainless steel knife valve is designed entirely in stainless steel 201, stainless steel 304, stainless steel 316 specialized for corrosive environments chemicals, salt water, wastewater,...

- Stainless steel knife valve is a fully closed / open valve, so it is not used to regulate the flow. Usually used for large pipe sizes, applied to hydroelectric power plants, medium and small, powder manufacturing plants. ,cement paper, etc...

- Stainless steel knife valve is a type of valve used to close or open, block or divide the fluid passing through the valve in the pipeline due to the action of the handwheel (steering wheel) operated by humans. With a valve-shaped structure, the valve disc is very thin and sharp, shaped like a shovel, the valve disc is like a blade raised and lowered to open and close the valve.

- Stainless steel knife valve is widely used for systems with solid, granular, corrosive fluids such as: thermal power, hydroelectricity, cassava, starch, coffee, petroleum, steam production systems. ,gas,...

Technical Stainless Steel Knife Gate Valve

- Size : 50A-80A

- Body: Inox 304,316,SUS304,SUS 316,CF8,CF8M

- Pressure range: PN10,PN16,PN25

- Temperature rangec: 0 ~ 180 độ C

- Media: wastewater, untreated wastewater, coal, cement, grease, paper, powder,...

- Origin: Taiwan,Korean,China,...

Application of Stainless Steel Knife Gate Valve

Supply water treatment plants, wastewater treatment plants, low water tanks, hydroelectric power plants, paper mills, chemical plants, etc.

- Cement plants

- Hydropower plants

- Paper factory

- Powder factory

- Purify water factory

- Water supply and drainage plant

- Industrial production plant

Cast Iron / Ductile Iron Knife Gate Valves

- What is a cast iron knife valve? It is also known as cast iron shovel valve, English name is Cast Iron Knife Gate Valves / Ductile Iron Knife Gate Valves, is a series of valves made of cast iron.

- This is a relatively popular and widely used valve line in industry. The cast iron knife valve is painted with a layer of epoxy paint to prevent rust to increase the service life of the valve and prevent corrosion as well as rust. for valve.

- Cast iron knife valve is a knife valve product made from 100% cast iron material. Cast iron material has the advantage of being used a lot in multi-purpose liquids. The heat is cheaper than stainless steel and steel but can be used a lot. environment.

- Cast iron knife valve has a flat structure, the disc is thin and flat, connected to the shaft and handwheel, when opening and closing, it is raised and lowered to suit the flow. Knife gate valve is made in many types of sizes. size, working pressure, working temperature, connection type, function and origin.

Technical Cast / Ductile Iron Knife Gate Valve

- Size of valve: DN50-DN1000

- Materials body of valve: Cast Iron / Ductile Iron

- Stem of valve: Stainless steel

- Dics of valve: Stainless steel 303, 316, 201, Cast steel, Cast Iron / Ductile Iron

- handwheel valve: Cast Iron / Ductile Iron

- Max. Pressure range: 10 bar,16bar, 20bar

- Max. Temperature range: 160 độ C

- Connection endsi: Flanged ends

- Standard: JIS, DIN, BS, ANSI

- Origin: Malaysia, Korea, China, Taiwan, Japan, EU, USA...

Application of Cast / Ductile Iron Knife Gate Valve

- Cast iron knife valve for wastewater treatment plant system, clean water, water filter

- Used for fire protection systems, air conditioners, hot and cold chillers

- Cast iron knife valve for hydroelectric and thermal power plants

- Cast iron knife valve is also used to install for ship systems, water pump room systems

- Used in the system of mining plants, coal, stone, iron, copper, aluminum, iron smelting

- Cast iron knife valves are also installed for breweries, soft drinks, and dairy systems

- Used in animal feed industry, paper mills, packaging, wood factories, ...

- Buy the right cast iron knife valve line suitable for the system that not only operates efficiently, saves time and costs but also is safe for users.Deciding to the success or not of the entire system.

Advantages - Defect of Cast / Ductile Iron Knife Valve

• Advantages of Cast Iron / Ductile Iron Knife Gate Valve

- Cast iron knife valve opens and closes without causing vibration

- Cast iron knife valve for many environments

- Cast iron knife valve can be installed in many high, low and buried positions

- Can be installed horizontally, vertically or diagonally

- Cast iron knife valve withstands high pressure, high temperature

• Defect of Cast Iron / Ductile Iron Knife Gate Valve

- Cast iron knife valve regulates large and small flow poorly

- Cannot be used in corrosive environments