PA (Polyamides) Plastic

What is PA Plastic?

-

Polyamides or Nylon is a major high performance engineering thermoplastics class because of its good balance of properties. Polyamides contain repeating amide linkages i.e. –CO-NH–. It is formed by condensing identical units, copolymers with different units.

-

There are various types of PA plastic are available. Polyamide is easy to work with and guarantees quality.

-

PA plastic has good mechanical properties and this plastic is mainly used in mechanical engineering.

-

PA Plastic is categorised as a technical plastic and is also known as an engineering plastic. Polyamide, more familiarly known as Nylon, is an extremely abrasion-resistant plastic.

Different Types of PA Plastic

-

These are including: Polyamide 6 (PA6), Polyamide 12 (PA12), Polyamide 66 (PA66), Polyamide 69 (PA69), Polyamide 6-10 (PA6-10), Polyamide 6-12 (PA6-12), Polyamide 46 (PA46), Polyamide 1212 (PA1212)

-

Typically, polyamides (or Nylon) are made from polycondensation of diacid with a diamine or by ring-opening polymerization of lactams with 6, 11 or 12 carbon atoms.

-

The monomers may be aliphatic, semi-aromatic or aromatic (aramids).

-

They may be amorphous, semi-crystalline and of greater or lesser crystallinity.

PA6 Plastic - Polyamide 6

-

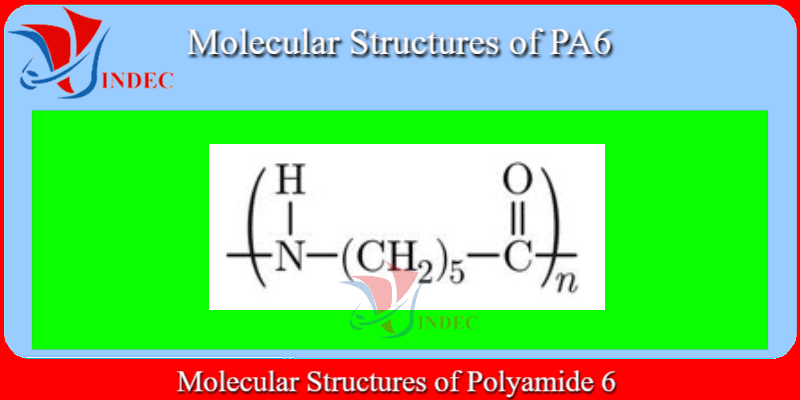

Polyamide 6 (PA6 Plastic) is also known as Nylon 6 or polycaprolactam. It is one of the most extensively used polyamides globally. It is synthesized by ring-opening polymerization of caprolactam. Melting point of polyamide 6 is 223°C.

-

PA6 Plastic is Caprolactum of Monomer(s)

PA66 Plastic - Polyamide 66

-

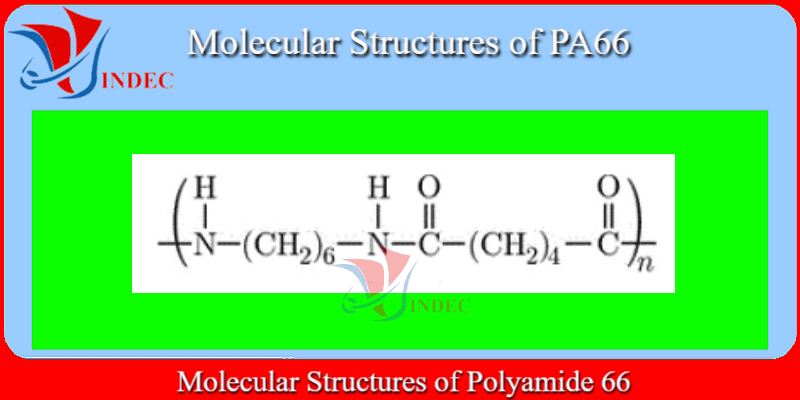

PA66 Plastic is Hexamethylene Diamine/ Adipic Acid of Monomer(s).

-

Polyamide 66 (PA66) or Nylon 66 is one of the most popular engineering thermoplastics and is majorly used as a replacement to metal in various applications.

-

Nylon 66 is synthesized by polycondensation of hexamethylenediamine and adipic acid (two monomers each containing 6 carbon atoms). Melting point of polyamide 66 is 255°C.

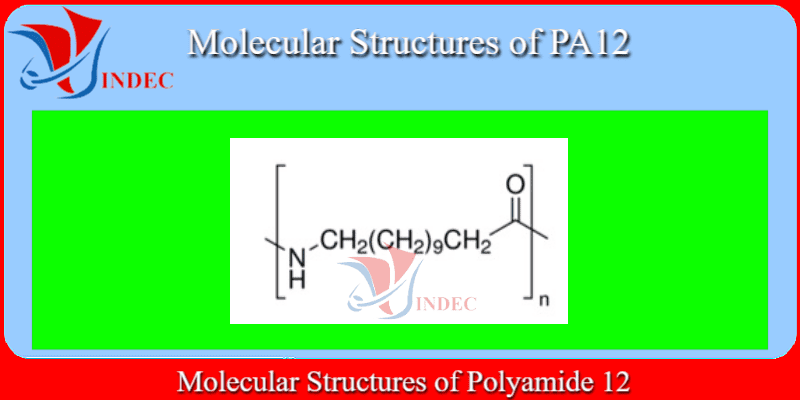

PA12 Plastic - Polyamide 12

-

PA12 Plastic is Laurolactam of Monomer(s)

-

Polyamide 12 (PA12) or Nylon 12 is a semi-crystalline thermoplastic which shows performance similar to Polyamide 11.

-

It can be derived from both petroleum and renewable sources. It is an expensive polymer as compared to other polyamides.

PA69 Plastic - Polyamide 69

-

PA69 Plastic is Hexamethylene Diamine/ Azelaic Acid of Monomer(s)

PA46 Plastic - Polyamide 46

-

PA46 Plastic is 1,4-Diaminobutane/ Adipic Acid

-

Polyamide 46 (PA46) or Nylon 46 is manufactured by polycondensation of adipic acid and 1,4-diaminobutane.

-

Diaminobutane is synthesized from acrylonitrile and HCN.

-

Melting point of polyamide 46 is 295°C.

PA6-10 Plastic - Polyamide 6-10

-

PA6-10 Plastic is Hexamethylene Diamine/ 1,12-Dodecanedioic Acid of Monomer(s)

-

Polyamide 6-10 (PA 6-10) is a semi-crystalline polyamide. PA 6-10 is produced by the polymerization of hexamethylene diamine with a dibasic acid i.e sebacic acid this this case.

-

Melting point of polyamide 6-10 is 223°C.

PA6-12 Plastic - Polyamide 6-12

-

PA6-12 Plastic is Hexamethylene Diamine/ Sebacic Acid of Monomer(s)

PA1212 Plastic - Polyamide 1212

-

PA1212 Plastic is 1,12-Dodecanediamine/ 1,12-Dodecanedioic Acid of Monomer(s)

How Many Types of PA Nylon Plastic

-

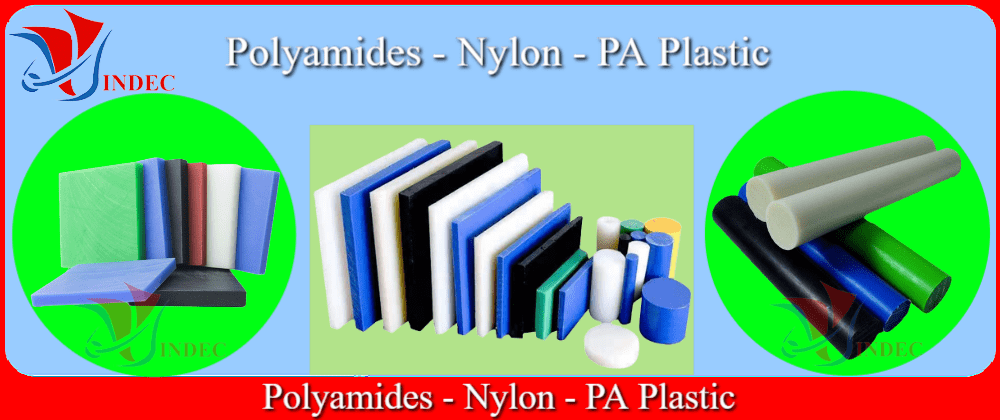

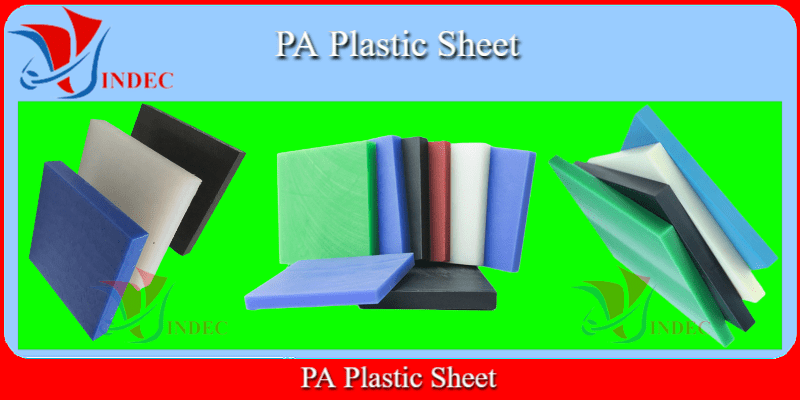

These are including: PA Plastic Sheet, PA Plastic Rod, PA Plastic Film

PA Plastic Sheet

PA Plastic Rod

PA Plastic Film

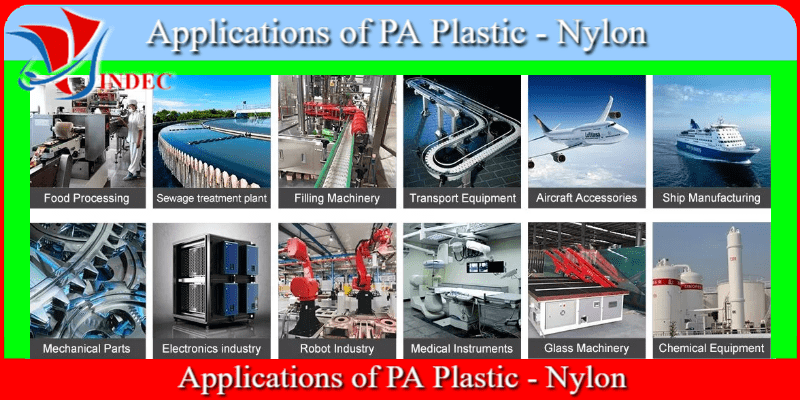

Applications of PA Plastic - Nylon