Piping Equipments

What are Piping Equipments ?

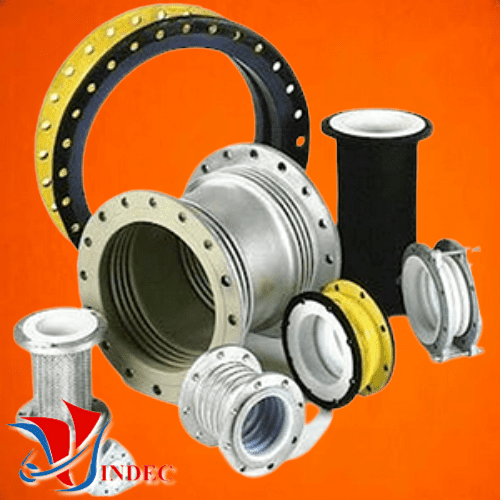

- The various types of piping equipment include gaskets, valves, flanges, actuators, pipes and fittings. The function of these tools are:

All Types of Piping Equipments

• Types of Flanges

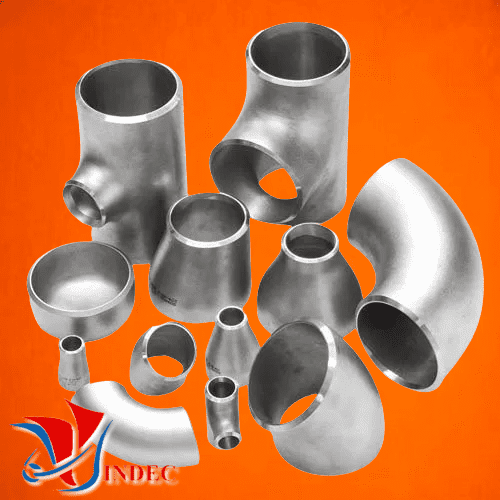

• Types of Butt Welding Fittings

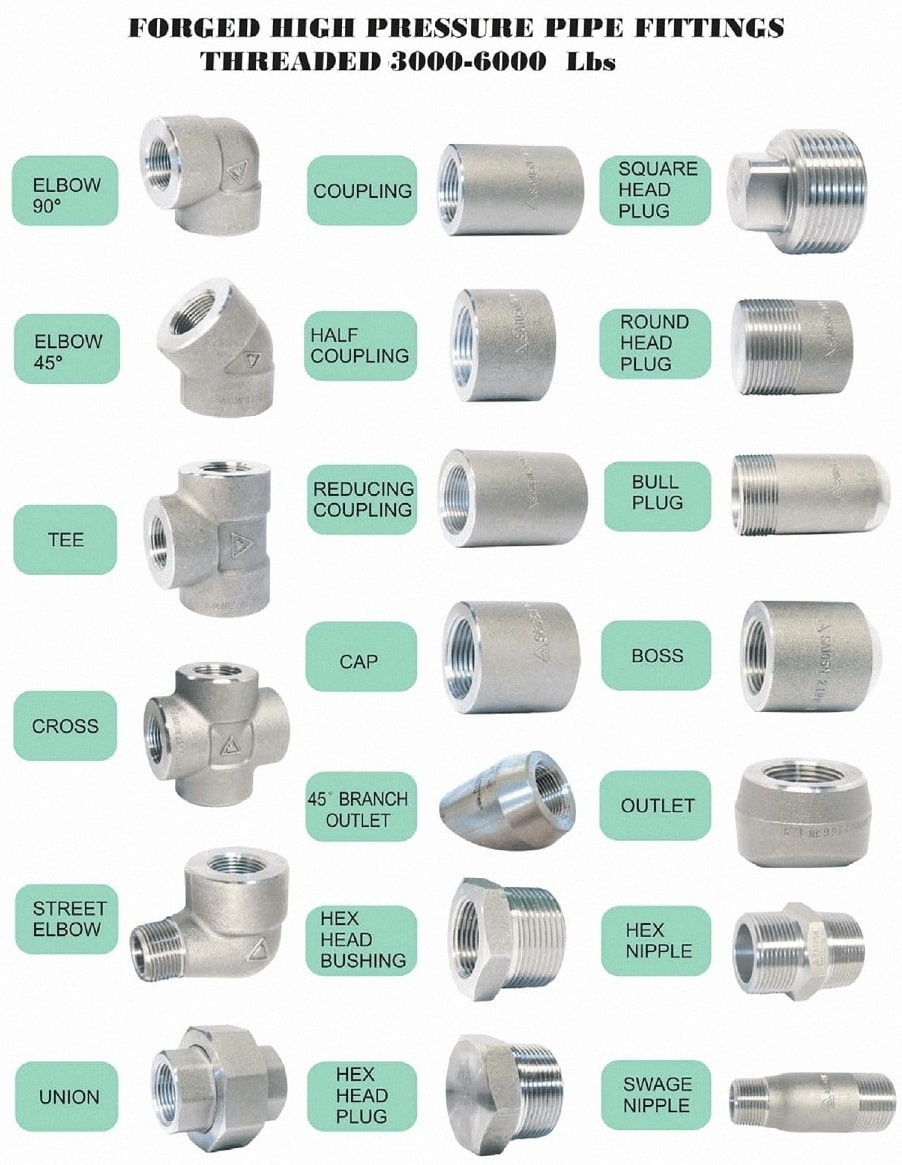

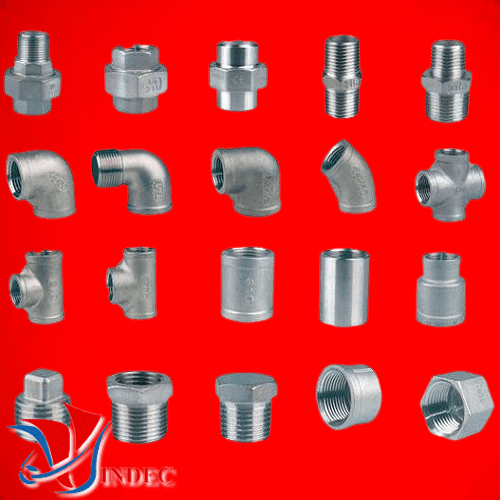

• Types of Threaded Fittings

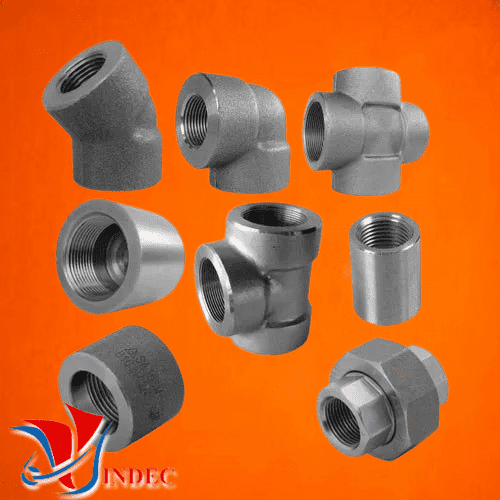

• Types of Forged Steel Fittings

• Types of Expansion Joints

• Types of Bolts - Nuts - Screws

• Types of Galvanized Malleable Iron Fitting

SW&THD fittings