Steam Traps

What is A Steam Trap ?

- Steam trap is the important device for a heat control . A heat control can not be carried out without this device

- Steam traps are also known as cot valves, steam cups, condensers, and condensers all have their English names as Steam traps. Steam traps are mechanical devices used to separate condensate from the system. This is a fully automatic operating valve to remove the water contained in the steam, or gas before entering the operating system.

- In the early years of the 18th century, after the industrial revolution, the type used hot steam in industrial production applications. In these early years the steam was normally removed by the drain valve, which was operated manually and lost a lot of steam. Then around 1860 metal steam traps began to be used, and in 1966 steam traps were developed.

Types of Steam Trap

• Mechanical Steam Traps

- Based on the law of the density of matter, mechanical steam traps designed apply the above law. The weight of the lighter gas or vapor is carried to the top and the heavier water should be condensed to the bottom and deposited in the container. When the amount of water in the tank reaches a large value, the float will be raised and the condensate in the container is discharged to the outside, and the float is gradually lowered and closed the drain cup. The valve is operated fully automatically, the process is continuously repeated to help steam and gas to be thoroughly treated to remove water and provide for the system to operate. There are two main types of mechanical steam traps: float steam traps and upside down steam traps

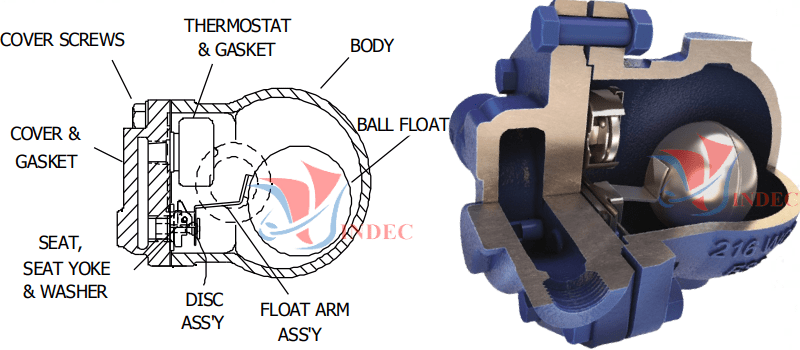

- Ball Float Steam Trap

Excellent durability of stainless steel disc, seat, and ball float. Inbuilt air vent assembly to eliminate air-binding. All parts are installed at the bonnet, and the integral bonnet would be helpful for easy maintenance.

+ Structure of Ball Float Steam Trap

+ Operation of Ball Float Steam Trap

What is A Float Steam Trap ?

- What are Float Traps ? Those are the common names of Ball Float Steam Traps. It has a working element which is a round metal ball that floats on condensate, hence the name float trap.

- Float steam trap is a thermal device used to discharge the condensate on the steam system and then discharge it will have to be pumped back into the boiler. Float steam traps have a faster and larger discharge flow than other types of steam traps.

- Using steam traps and return pumps helps to reduce steam consumption and helps save fuel for boilers.

Structure of Float Steam Trap

Operation of Float Steam Trap

- When the system starts up, the air and condensate begin into the steam trap. The air will be released through the thermostatic air vent, then the condensate enters and lifts the float up, the mechanical mechanism opens the valve to let the condensate out.

- When the float is lowered, the mechanical mechanism closes the valve, this valve always holds below the water surface, so the heat cannot escape. The up-down float makes the valve open and close continuously at different angles and balance between the incoming condensate and the outlet condensate.

- For the discharge flow and balance the force of the incoming steam pressure, the internal structure of the common steam trap has many options of valve size (orifice) to needs of discharge flow and pressure working capacity of steam trap.

- When steam begin the steam trap, the thermostatic expands and closes the thermostatic air vent, preventing steam from escaping. When the condensate drains out, the float lowers and causes the mechanical mechanism to close the orifice valve.

- Bucket Steam Trap

It is and inverted type steam trap suitable for the heat exchangers, dryers and steam press, constructionally solving the air trouble by itself. All of the working parts are installed at the inside of the bonnet for easy disassembly and maintenance.

+ Structure of Bucket Steam Trap

+ Operation of Bucket Steam Trap

• Thermostatic Steam Traps

- Typical characteristics of thermostatic steam traps is to aperate according to the difference in temperature of steam and condensate. As the condensate cool, the liquid condenses lowers the internal pressure of the membrane. The resultant pressure differential will favor the external pressure acting on the membrane to retract and open the orifice, permitting the condensate discharge.

- Based on the difference in temperature, the pressure should be equal and the thermal expansion. Thermostatic steam traps are used to remove water from the steam, before entering the operating system. The principle of operation of a thermostatic steam trap is based on the expansion of hot steam and the contraction of condensate, so the steam trap operates on the control of heat and condensate. Thermostatic steam traps work well in saturated steam systems, in addition to having the ability to discharge condensate at system start-up. The most commonly used thermostatic steam traps are bimetallic steam traps.

- Types of Thermostatic Steam Traps : Liquid Expansion, Balance Pressurized, Bi-metallic, Bellowed.

- Insulation chamber(air warm) is adopted to lessen the affect of atmosphere and to improve the most suitable working conditions.

- The maintenance and repair of disc and are easy owing to its material of high-hardness-treated stainless steel and its replaceable seat.

- Bẫy Hơi Lưỡng Kim

+ Cấu Tạo Bẫy Hơi Lưỡng Kim

+ Nguyên Lý Hoạt Động Bẫy Hơi Lưỡng Kim

• Thermodynamic Steam Traps

- Thermodynamic steam traps operate periodically according to the difference in dynamic pressure of steam and condensate and discharge the condensate at the same temperature of the steam. Steam entering the trap expands suddenly as it reaches the backside of the disc. The resulting high flow velocity causes a decrease in pressure under the disk. Steam above the disc gets high pressure force and this pressure balance forces the disc onto the seat to close the orifice in other words to trap the steam.

- When condensate appears at the trap inlet under and above the disc the pressure force above the disc disappears and allows the condensate discharge.

- Based on the difference of pressure, velocity, flow, thermodynamic steam trap works on the above difference. When starting the system steam enters the thermodynamic steam trap, the pressure causes the valve disc to rise to the condensate and the air is immediately released. When steam is released at high velocity, high velocity creates low pressure under the valve disc and pushes the valve disc to the belt, When pressure on the valve disc is formed in the chamber pushing the valve disc downward and against condensate . And when the pressure on the disc is reduced, the disc is lifted and the condensate is pushed out. The most commonly used thermodynamic steam trap in the market is the coin steam trap.

- Types of Thermodynamic Steam Traps : Disc Type, Steam Jacketed

- Disc Steam Trap

+ Structure of Disc Steam Trap

+ Operation of Disc Steam Trap

Application of Steam Trap

- For Application to larger capacity than thermodynamic trap such as heat exchanger, dryer, chemical plant, and various steam systems.