Diaphragm Valves

What is A Diaphragm Valve ?

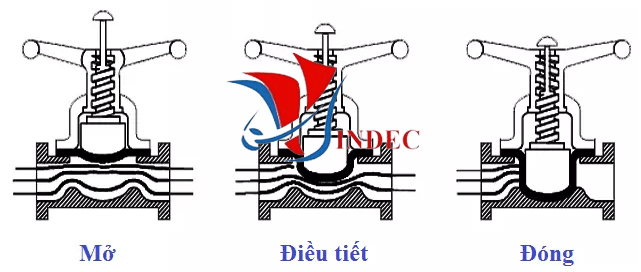

- Diaphragm valve utilize a flexible diaphragm to obstruct, control, or isolate the flow of fluids. The diaphragm acts as the flow control element that flexes up or down to increase or decrease the fluid flow rate, respectively. The sealing action of the valve is created as the diaphragm is pressed onto the solid dam inside the valve body. Diaphragm valves are classified as linear motion valves, which require linear motion of the flow control element.

Structure of Diaphragm Valve

Operations of Diaphragm Valve

Operations of Diaphragm Valve

Types of Diaphragm Valves

- The two main types of diaphragm valves are the straight and weir through diaphragm valves, which only differ on the valve body and diaphragm design.

• Weir Diaphragm Valve

- The weir-type design is the most popular diaphragm valve design

• Straight Through Diaphragm Valve

• Zero Static Diaphragm Valve

• Sanitary Diaphragm Valve

• Process Diaphragm Valve

• Hygienic Diaphragm Valve

• Biotech Diaphragm Valve

Pneumatic Operated Diaphragm Valve

Advantages of Diaphragm Valve

- Can be used as on-off valves or damper.

- Provides good chemical resistance due to a variety of lining materials.

- No Leakage Through Ty

- Provides bubble-tight . functionality

- There is no space in the valve body to trap solids, dirt, and other impurities. Diaphragm valves are suitable for liquids and viscous liquids.

These valves are especially suitable for hazardous chemicals and radioactive substances.

These valves do not allow contamination of the fluid flow, so they are widely used in food processing, pharmaceuticals, brewing, and other applications where contamination cannot be allowed.

Defect of Diaphragm Valve

- The diaphragm can prevent the complete drainage of the pipeline.

- Working temperature and pressure are limited by membrane material. Generally the limit pressure is 200 psi (1380 kPa) and the maximum temperature is up to 400 F (204 C).

- The membrane can also limit the hydrostatic pressure.

- Membrane may wear out with heavy use in control function containing impurities.

- Diaphragm valves are limited in size, usually NPS ¹/₂ to 12 (DN 15 to DN300).

Applications of Diaphragm Valve

- Clean water system, Domestic Water system, waste water system and air system applications.

- Demineralized water system

- Corrosive applications

- Radioactive waste systems in nuclear facilities

- Vacuum function

- Food processing, pharmaceutical, and brewing systems.

- Effective application for processes with corrosive, abrasive as well as high viscosity fluids, such as acids, caustic soda, lubricants... in chemical and fertilizer factories, and especially diaphragm valves. Widely used in pharmaceutical and food manufacturing plants.