Spiral Wound Gaskets

SPIRAL WOUND GASKET

- What is A spiral wound gasket? ASpiral Wound Gasket (Gioăng thép xoắn) is the most common metallic gasket used in industrial plants. A properly selected and installed spiral wound gasket can withstand high temperatures and pressures, preventing leaks throughout their intended lifespan.

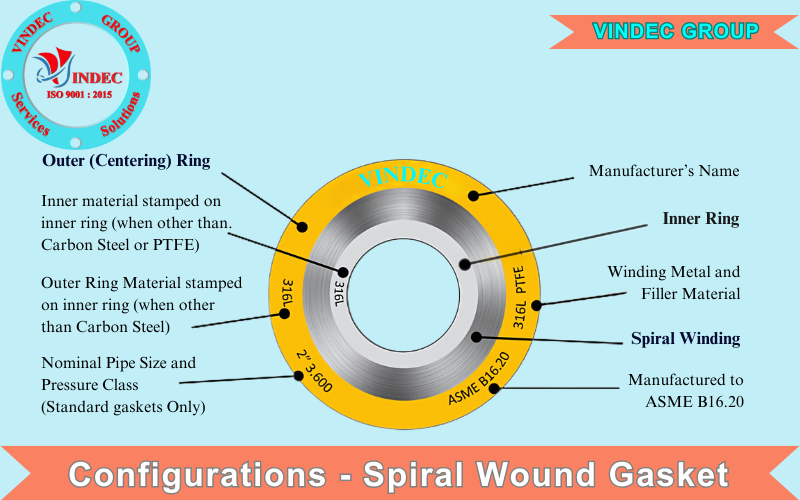

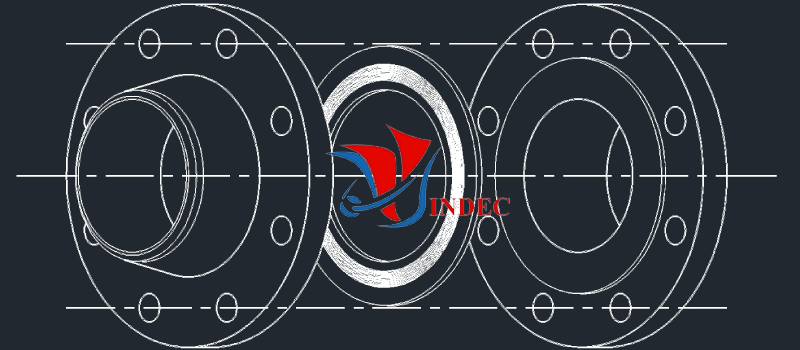

STRUCTURE of SPIRAL WOUND GASKET

- A spiral wound gasket consists of three elements as bellow:

Outer ring of spiral wound gasket

- Made of carbon steel, this outer ring is sometimes called the centering ring or guide ring. It’s used to center the gasket when you insert it into a bolted flange joint.

Inner ring of spiral wound gasket

- The inner ring is pivotal for the gasket because it prevents windings from buckling inside the pipe. When a gasket buckles, parts of it get sucked into the pipe.

- From there, pieces of the gasket will typically flow through the pipeline until they get caught on something. Often, they’ll get wrapped around rotating equipment like a pump.

- The mess that results is known as a “bird’s nest.” Inner rings help you avoid this problem.

Sealing element of spiral wound gasket

- As you might guess from the name, the sealing element creates the seal that prevents leaks. A sealing element encompasses both windings and filler material.

- Most spiral wound gaskets in oil and gas refineries will use a flexible graphite filler material rated for high temperatures.

- A flexible graphite filler also allows the gasket to be more tolerant of flange distortion and joint misalignment.

- Polytetrafluoroethylene (PTFE) is another common filler material.

- PTFE is not rated for high-temperature applications, however. Mean while, most winding materials in refineries will be stainless steel and monel.

Installation Guide for Metallic Gaskets

- A gasket has one basic function: to create a positive seal between two relatively stationary parts. The gasket must do several different jobs well to function properly - first, create an initial seal; second, maintain the seal over a desired length of time; third, be easily removed and replaced. Varying degrees of success are dependent on how well the gasket does the following this video:

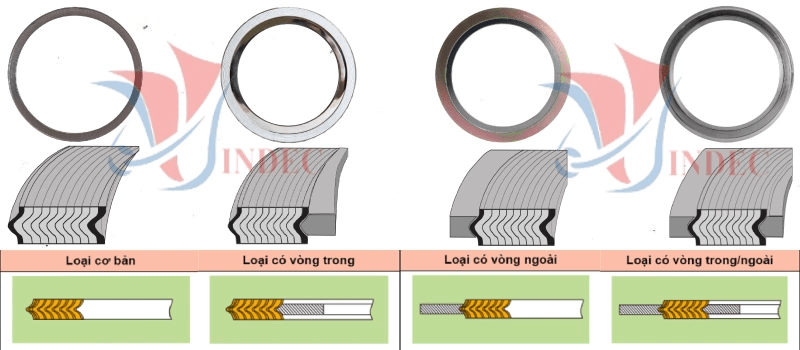

Types of Spiral Wound Gaskets

Spiral Wound Gasket

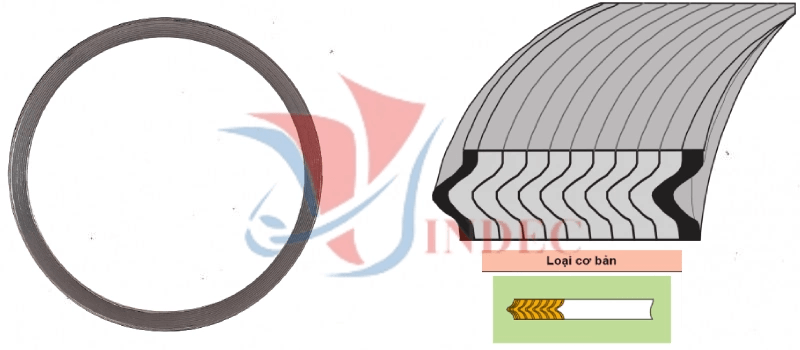

Spiral Wound Gasket without Rings

- - Spiral wound gaskets without centering and inner ring Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical, and arduous duties.

- - Is comprised of a sealing element, additional plies of metal are used at the start and termination of the winding process improving stability and sealing performance. Unlike other styles of spiral wound gasket compression of the sealing element is controlled by the use of the correct flange face configuration, This style spiral wound gasket is suitable for use on tongue and groove, male and female and flat to groove flanged connections.

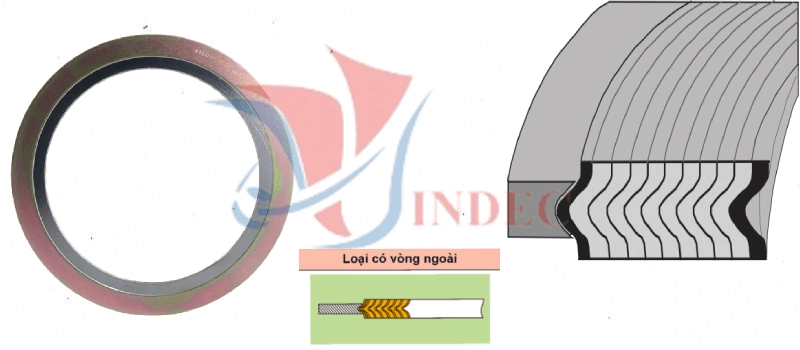

Spiral Wound Gasket with Outer Ring

- - Manufactured to International specifications such as BS, API, ASME, DIN. We also manufacture to customer's specifications. We have a huge capacity to produce precision machined components.

- - Is comprised of a sealing element and outer metal ring. The outer ring assists in locating the gasket on the mating flange faces and prevents over compression of the sealing element ensuring optimum sealing performance.

- - This style spiral wound gasket are suitable for use on raised and flat faced flanged connections. This style spiral wound gasket is suitable for use in mild to moderate service conditions.

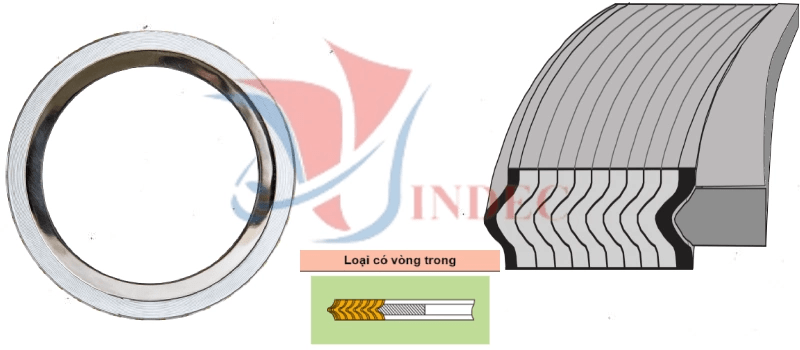

Spiral Wound Gasket with Inner Ring

- - Spiral wound gaskets with inner centering ring Spiral wound gaskets have proven to be the most reliable sealing element for use in difficult, critical and arduous duties.

- - Is comprised of a sealing element and inner metal ring. The inner ring functions as both a compression stop and creates a physical barrier between the sealing element and media stream. The inner ring is also designed to reduce turbulent flow, minimising flange erosion and prevents the build up debris in the annular space between the pipe bore and internal diameter of the gasket.

- - This style spiral wound gasket is suitable for use on male and female (spigot and recess) flanged connections.

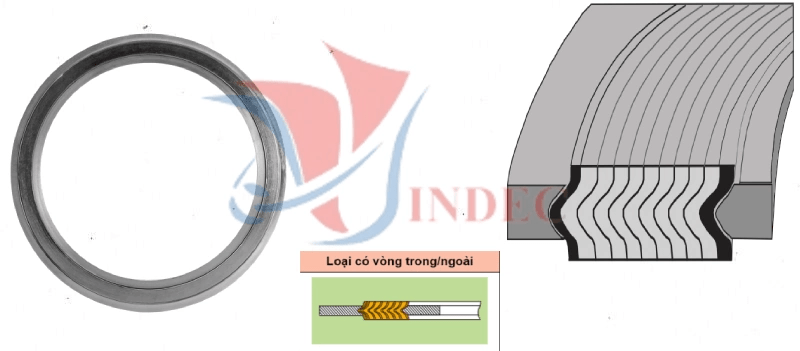

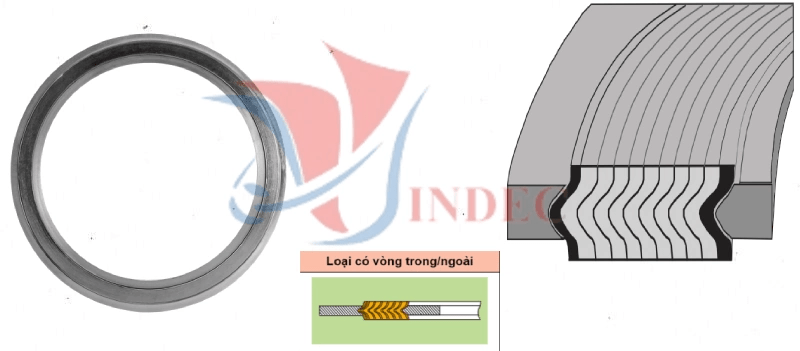

Spiral Wound Gasket with Inner & Outer Ring

- - Manufactured of a spiral-wound metal strip and a non-metallic filler material. The metallic outer centering ring controls the compression and holds the gasket centrally within the bolt circle. The inner retaining ring increases the axial rigidity and resilience of the gasket.

- - In addition to an outer metal ring this style spiral wound gasket is fitted with an inner metal ring, constraining the sealing element on both internal and external diameters. The inner ring functions as an additional compression stop and prevents inner buckling of the sealing element. It also creates a physical barrier between the sealing element and process stream shielding from heat and media while preventing erosion.

- - This style spiral wound gasket are suitable for use on raised and flat faced flanged connections and moderate to severe service conditions.

Materials of Spiral Wound Gasket

Spiral Wound Gasket Color Codes

- Colors play an important role on spiral wound gaskets. The color of the outside rim, and the color of the stripe along the rim, both are important indicators of the material within the gasket.

- • Outside rim colors indicate the gasket’s windings materials

- • Rim stripe colors tell you the gasket’s filler materials

- For example, the following outside rim colors indicate specific windings materials:

- - Yellow means 304 stainless steel gasket material. That means the inner ring and metallic windings are made of 304 stainless steel.

- - Green is 316 stainless steel.

- - Turquoise is 321 stainless steel.

- - Blue is 347 stainless steel.

- - Orange means that it’s made out of Monel.

- - Black is Alloy 20

- - Silver is carbon steel

- - Brown is Hastelloy B

- - Beige is Hastelloy C

- - Gold is Iconel

- - Red is Nickel

- - Purple is Titanium

- NOTE: If you work in the oil and gas industry, most of the time you will see one of three colors: Yellow (304 stainless steel), Green (316 stainless steel), or Orange (monel). Monel is an alloy of nickel and copper that, in addition to tolerating high-temperatures, also is resistant to corrosion.

- Mean while, rim stripe color tells you the gasket has one of the following filler materials:

- - Pink indicates mica paper

- - Gray indicates graphite

- - White indicates PTFE

- -Light Green green indicates ceramic

- NOTE: If you work in the oil and gas industry, most of the time you will see Gray, indicating graphite.

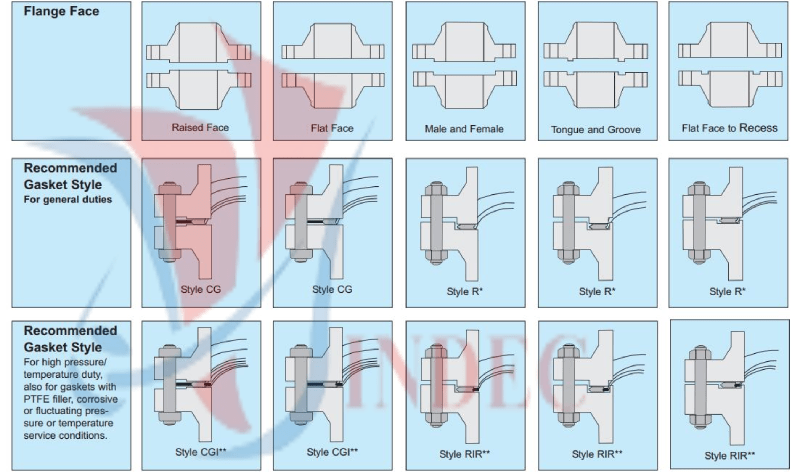

How to Choose Spiral Wound Gasket for Flange

Types of Spiral Wound Gasket for Flange

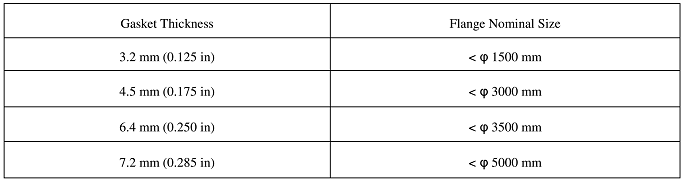

Thickness of Spiral Wound Gasket

Key Features of Spiral Wound Gasket

- Good compression recovery, suitable for high temperature, high application

- Used for corrosive liquid, gas, hot steam valve, oil tank, gas ...

- Metal gasket surface wave sealing is very good, can be reused.

- Used in low and high temperature conditions both used (-200 ° C ~ + 700 ° C), it can also be used for high and applied (vacuum ~ 25Mpa).

- This kind of metal gasket with high performance is designed for the face of the face lift and the plane

- It has the ability to recover the operation of the dangerous energy oscillation during the application process and the temperature of the liquid changes, causing the contact surface of the scraper to deform, the moon to rotate, the feather to stretch and deform.

Application of Spiral Wound Gasket

- Refinery, Petrochemical, Chemical, Steam lines and Process Industries

Admin: VINDEC