Flanges Standards

What is A Flange?

Wellgrow offers a wide range of flanges, pipe flanges, tube flanges, din flange, dn flanges, pn flanges, ansi flang, asme flanges, jis flanges, bs flanges, en flanges, 150# flanges, rtj flanges, raised face flanges, rf flanges, loose flange, flat face flanges, ff flanges, weld flanges, weld on flanges, welding flanges, weld neck flanges, welding neck flanges, welded flanges, weldneck flange, slip on flanges, plate flanges, blind flanges, flat flanges, socket weld flanges, socket flanges, orifice flanges, threaded flanges, lap joint flanges, spectacle flanges, spectacle blind, orifice plate, steel flanges, carbon flanges, carbon steel flanges, stainless flanges, stainless steel flanges, metal flanges, based on guaranteed quality.

Common production as world standards include ASA/ANSI (USA), PN/DIN/EN (European), BS10 (British/Australian), BS4504 (British/Australian) and JIS (Japanese).

Our flanges are made by forging or casting according to clients’ request. Further, the industrial flanges in each standard are divided into pressure classes, allowing flanges to be capable of taking different pressure ratings.

These pressure classes also have differing pressure and temperature ratings for different materials.

In ASA/ANSI flange, our pressure rating includes 75PSI, 150PSI, 300PSI, 400PSI, 600PSI, 900PSI, 1500PSI and 2500PSI.

In PN/DIN/EN/BS, our pressure rating includes PN2.5, PN6, PN10, PN16, PN25, ,PN40, PN64, PN100, PN160, PN250, PN320 and PN400.

And our pressure rating for JIS flange covers 2K, 5K, 10K, 16K, 20K, 30K, 40K and 63K.

We can offer carbon steel in ASTM/ASME A/SA105 A/SA105N & A216-WCB, DIN1.0402, DIN1.0460, DIN1.0619 and stainless steel in ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN1.4301, DIN1.4306, DIN1.4401, DIN1.4404, DIN1.4308, DIN1.4408, DIN1.4306, DIN1.4409 material to satisfy you.

Our flange faces are also made to standardized dimensions and are typically flat face (FF), raised face (RF) or ring joint (RJT) styles. Flange designs are available as weld neck flange (WN), slip-on flange (SO), lap joint flange (LJ), socket weld flange (SO), threaded / screwed flange (TH), blind flange (BL), plate flange (PL), orifice flange, orifice plate, spectacle blind, spectacle flange, blind spacer and also blank.

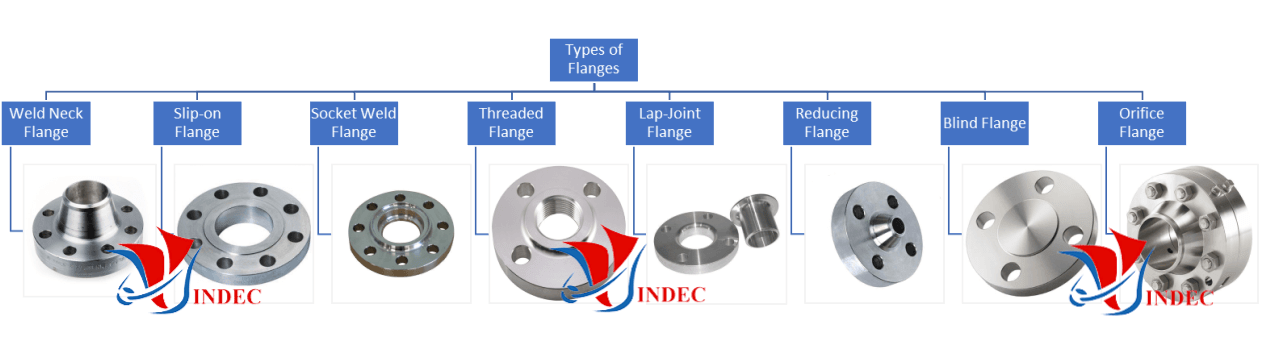

Types of Flanges

Types of Flanges

Connections of Flanges

• Flat Face Flange (FF Flange)

• Raise Face Flange (RF Flange)

• Ring Type Joint Flange (RTJ Flange)

• Tongue and Groove Flange

• Male - Female Flange

Types of Flanges Standard

• JIS Flanges Standard

JIS5K, JIS10K, JIS20K, JIS30K, JIS40K....

The standard of JIS B2220 covers blind flange (BL), slip on flange (SOP), plate flange (PL) and weld neck flange (WN) for sizes from 10A up to 1500A diameter, in rating classes of 2K, 5K, 10K, 16K, 20K, 30K, 40K and 63K.

• DIN Flanges Standard

- DIN Flanges Standard

DIN 2527, DIN2573, DIN2576, DIN2543, DIN2544, DIN2545, DIN2502, DIN2503, DIN2503, DIN2630, DIN2630, DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2628, DIN2629, DIN2627, DIN 2641, DIN2642, DIN2652, DIN2653, DIN2655, DIN2656, DIN2673, DIN2674, DIN2675, DIN2676, DIN2558, DIN2561, DIN2565, DIN2566, DIN2567, DIN2568, DIN2569, DIN28115, DIN86029, DIN86030

- Types of Flanges Standard

Blind Flange, Flat Flange for welding (Slip On), Welding Neck Flange, Lapped (Lapped Joint) Flange, Loose Flange and Ring for Weld (Slip-On Flange and Plain Collar), Loose Flange and Ring with Neck for Welding, Oval Plain Threaded Flange, Oval Flange with Neck Threaded, Threaded Flange with Neck, Long Neck Welding Flange, Hubbed Slip On Flange for Welding,

- Our pressure rating includes PN1, PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, PN250

• BS Flanges Standard

PN5, PN10, PN16, PN25, PN40,...

The standard of BS10 Table D, E, F, H, J, K, R, S, T covers Slip On Boss, Plate Blind, Weld Neck, Plate Slip On, Bossed Screwed / Threaded for sizes up to NB4000. As for BS4504 Section 3.1: 1989 specification, we can offer Slip On Plate (Code 101), Blind / Blank (Code 105), Weld Neck (Code 111), Slip On (Code 112), Screwed / Threaded (Code 113) for size range is DN10 through to DN4000 diameter and class rating includes PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN100. Our line also Involves BS1042 for Concentric Square Edge Orifice Plate, Quarter Circle Orifice Plate, Conical Entrance Orifice Plate, Restriction Orifice Plate, Segmental Orifice Plate and Eccentric Orifice Plate.

• ANSI Flanges Standard

ASME B16.5, B16.47, B16.48, B16.36: #150; #300; # 600; #900; #1500; #2500

The standard of ASME/ANSI B16.5 covers weld neck flange, threaded / screwed flange, slip on flange, socket weld flange, lap joint flange, blind flange for sizes up to 24" diameter, in rating c lasses of 150, 300, 400, 600, 900, 1500 and 2500. As for ASME/ANSI B16.47 Series A (MSS SP-44) and ASME/ANSI B16.47 Series B (API 605) for weld neck flange & blind flange, the size range is 26" through to 60" diameter. In series A, our class ratings are for 150lb, 300lb, 400lb, 600lb and 900lb. In series B, our class ratings are for 75lb, 150lb, 300lb, 400lb, 600lb and 900lb. Our ASME/ANSI B16.36 Orifice Flanges including weld neck, slip on, threaded (screwed) type, covers sizes from 1" to 24" in rating classes of 300lb, 400lb, 600lb, 900lb, 1500lb and 2500lb. And ASME/ANSI B16.48 (API 590) for Spacer, Blanks, Spectacle Blinds for size up to 24” diameter, in pressure class 150lb, 300lb, 400lb, 600lb and 900lb.

• API 6B Flanges Standard

API 3000, API 5000, API 10000

• EN1092-1 Flanges Standard

The standard of EN1092-1 flanges (EN flanges) involves Type 01 Plate (slip on) Flange for Welding, Type 02 Loose Plate Flanges with Weld On Plate Collar or for lapped pipe end, Type 04 Loose Plate Flanges with Weld Neck Collar, Type 05 Blind Flange, Type 11 Weld Neck Flange, Type 12 Hubbed Slip On Flanges for Welding, Type 13 Hubbed Threaded Flanges, Type 21 Integral Flange, Type 32 Weld on Plate Collar, Type 33 Lapped Pipe End, Type 34 Weld neck Collar, Type 35 Welding Neck, Type 36 Pressed collar with long neck, Type 37 Pressed Collar. The types of EN1092-1 flanges and collars are type no. 01, 02, 04, 05, 11, 12, 13, 21, 32, 33, 34, 35, 36 and 37. According to specification, type number 32, 33, 35, 36 and 37 are for use with type 02 flange and type number 34 for use with type 04 flange. Our available size range is from DN10 up to DN4000 diameter and pressure rating includes PN2.5, PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160, PN250, PN320, PN400.

Types of Flanges Connected Piping

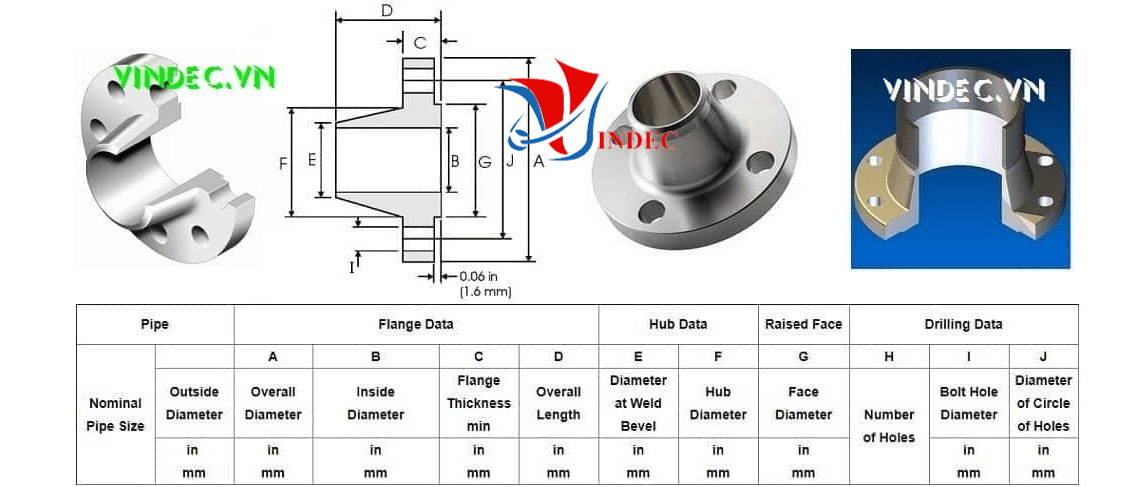

• Welding Neck Flange (WN Flange)

Weld necks are the most popular flange in service because they allow for single weld attachment of the flange to the pipe. During welding, the transfer of heat is reduced to the stress of the flange face because of the distance of the weld.

Weld neck flanges are installed by welding the pipe to the neck of the flange. This allows for the transfer of stress from the flange to the pipe itself. This also reduces high-stress concentrations at the base of the hub.

Welding Neck Flange

WELDING NECK FLANGE

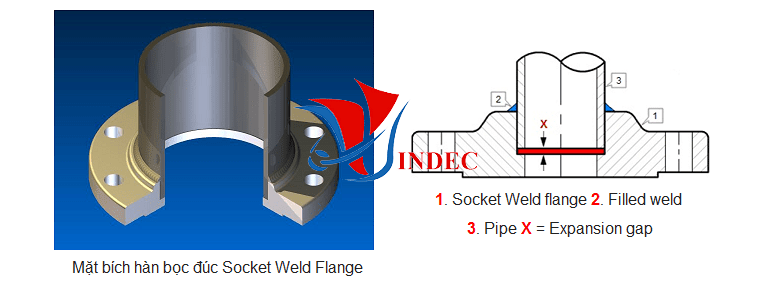

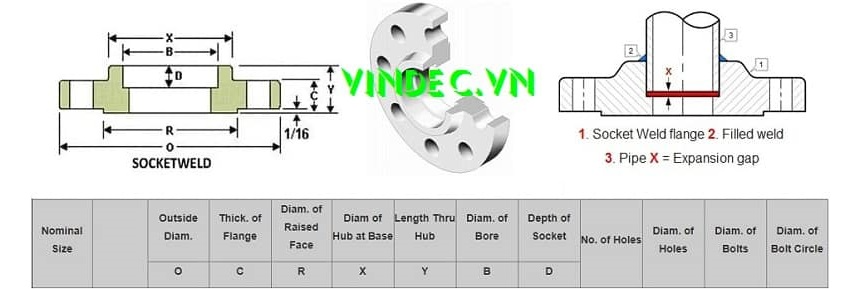

• Socket Weld Flange (SW Flange)

Socket Weld Flange

SOCKET WELD FLANGE

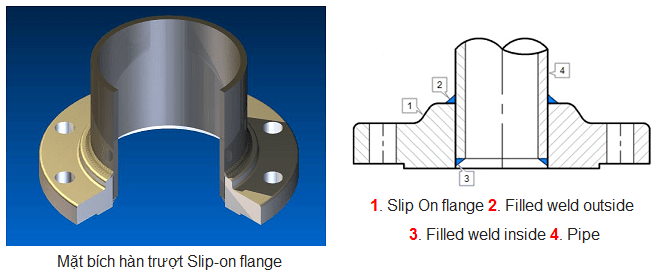

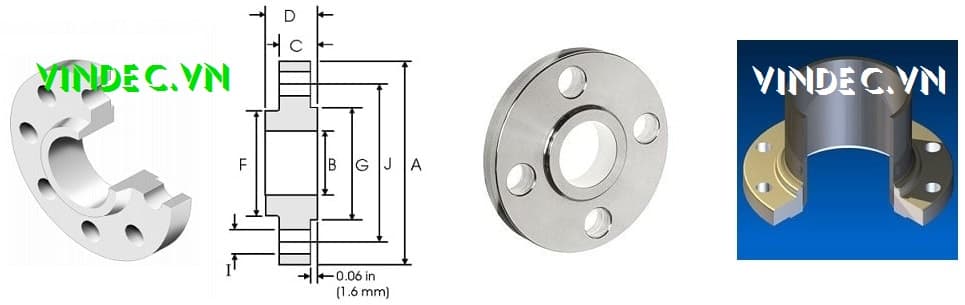

• Slip-On Flange (SO Flange)

Slip-on flanges have a hub that slides over the pipe and requires two weld attachments front and back of the flange. Slip-on flanges have less weight than a weld neck, making a more cost-effective option.

Slip-on flanges as described by its name, slides over the pipe. They are typically machined with an inside diameter slightly larger than the outside diameter of the pipe. This allows the flange to slide over the pipe, but still maintain a snug fit. Slip-ons are secured to the pipe with a filet weld at the top and bottom of the flange.

SLIP ON FLANGE

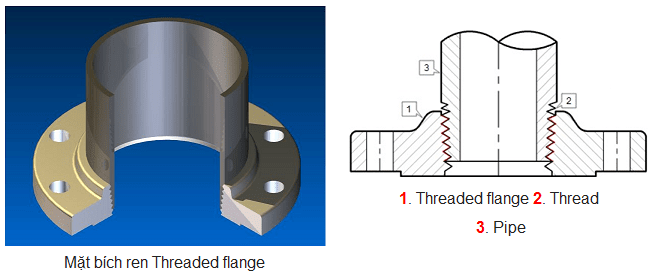

• Threaded Flange (TF Flange)

Threaded Flange

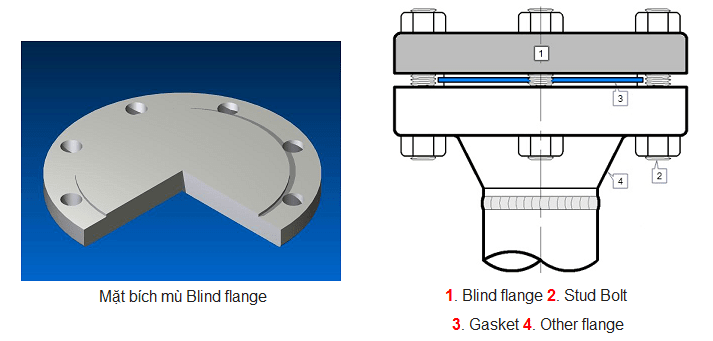

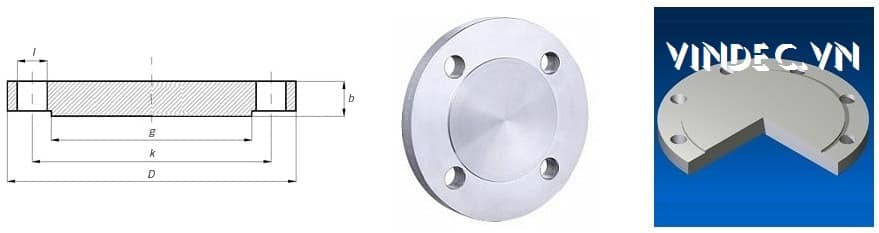

• Blind Flange (BF Flange)

Blind flanges are used in the oil and gas industry to cap off a weld neck or slip-on flange to close or seal the pipeline. These flanges are usually purchased solid in combination with a weld neck or slip-on flanges for completion of the pipeline.

Blind flanges are used to seal the end of a piping system or pressure vessel openings to prevent flow. They are used for testing the flow of liquid or gas through a pipe or vessel.They allow for an easy access in the event that work must be done inside the line.

BLIND FLANGE

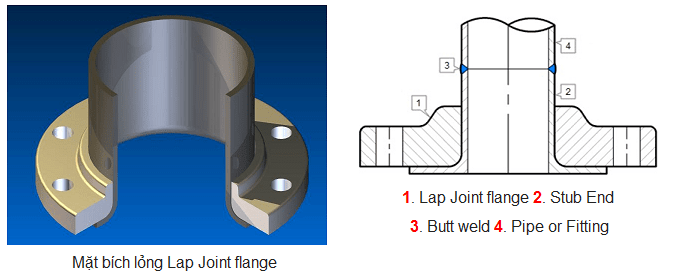

• Lap Joint Flange (LJ Flange)

Materials of Flanges

• Cast Steel Flange

• Forged Steel Flange

• Forged Stainless Steel Flange

• Stainless Steel Flange

• Plastic Flange

• Copper Flange

• Aluminum Flange

Applications of Flanges

- Flanges for High volume valves and vessels

- Flanges for Industrial pumps and manufacturing systems

- Flanges for Food and beverage processing

- Flanges for Large scale pipe systems and waterworks

- Flanges for Heat exchangers and systems

- Flanges for Nuclear power plants and Power plants

- Flanges for Oil, gas drilling and and chemical assemblies.

- Flanges for Petrochemical treatment and processing

- Flanges for Waterworks and municipal pipe systems.

- Flanges for Fire protection services.

What is Types of Flanges

- VINDEC supply flanges used extensively with pipe fittings in all kinds of industrial applications,including: natural gas,chemical,petroleum,ship building,marine,paper making,metallurgy,electric,power,boiler,etc. Depending on different applications, we have the following materials for the flanges:

- Carbon steel flange: ASTM A105,ASTM A105N,GB 20,C22.8. Alloy steel: ASTM/ASME A234 WP 1-WP 12-WP 11-WP 22-WP 5-WP 91-WP 911

- Stainless steel flange: ASTM/ASME A403 WP 304-304L-304H-304LN-304N ASTM/ASME A403 WP 316-316L-316H-316LN-316N-316Ti ASTM/ASME A403 WP 321-321H ASTM/ASME A403 WP 347-347H

- Low temperature steel flange: ASTM/ASME A402 WPL 3-WPL 6

- High performance steel flange: ASTM/ASME A860 WPHY 42-46-52-60-65-70

- Our flanges are usually according to different standards for different customers and projects:

+ America standard: ANSI B16.5,ANSI B16.47,ETC.

+ German standard: DIN 2573/DIN 2576/DIN 2631/DIN 2632/DIN 2633/DIN 2634/ DIN2635/DIN 2527 Japen standard: JIS B2220

+ Europe standard: BS4504/BS 10/UNI 2276 UNI 2277/UNI 2278/ UNI 6089/UNI 6090/EN 1092.

+ Stainless Steel Flanges, Alloy Steel Flanges, Carbon Steel Flanges, Duplex Steel Flanges, Monel Flanges & Inconel Flanges, ASTM / ASME - A 182 / 240, SA 182 / 240 Flanges,

Types & Applications of Flanges

We offer a wide range of standard and customized flanges to meet the varied requirements.

Weld Neck Flange (WN Flange)

Long Weld Neck Flange (LWN Flange)

Slip On Flange (SO-Flange)

Raised Face Flanges

Threaded Flange (THR Flange)

Blind Flange (BL Flange)

Plate Flange (PL Flange)

Groove Flanges

Socket Weld Flange (SW Flange)

Lap Joint Flange (LJ flange)

Orifice Flange

Other Types of Flanges

150Lbs Flanges

300Lbs Flanges

600Lbs Flanges

900Lbs Flanges

1500Lbs Flanges

2500Lbs Flanges

DIN Flanges PN6-PN40

ANSI B16.5 Flanges

ASME B16.47 Series A Flanges

ASME B16.47 Series B Flanges

ANSI B16.36 Orifice Flanges