What is NBR Rubber ?

-

Nitrile rubber sheeting (NBR) is a synthetic material that is used in a wide range of applications due to its resistance to most petroleum based fluids, oils and greases. Nitrile offers moderate mechanical properties and has satisfactory resistance to aromatic hydrocarbons, but is not suitable for use with ketones. If improved or specific material characteristics are required we offer BS 2751, blue food quality, white food quality and blue metal detectable nitrile grades that comply with British and American regulations.

Nitrile rubber sheeting can be cut to suit your requirements utilising CNC machinery into gaskets, supplied by the roll, or manufactured into sleeves. It is also available to buy online at PAR Direct by clicking the link above.

Nitrile rubber is also referred to as Buna-N, NBR rubber and Perbunan.

NBR Rubber Flange Gasket

- Specific gravity: 1.4 g/cm3 to 1.49 g/cm3

- Hardness: 65+/-5 to 70+/-5 shore A

- Tensile strength: 3mpa, 5mpa, 8 Mpa to 10 Mpa

- Temperature: -20 - 120 độ C

- Pressure Max. (bar): 10 Bar

- Color: White / Black

- Size: DN 8, 10, 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200, 250, 300, 350, 400, 450, 500...

- Standard: ANSI, DIN, JIS, BS...

Technical NBR Rubber Sheet

- Specific gravity: 1.4 g/cm3 đến 1.49 g/cm3

- Tensile strength (Mpa): 3mpa, 5mpa, 8 Mpa to 10 Mpa

- Hardness ( shore A): 60+/-5 to 70+/-5 shore A

- Pressure range (bar): 10 Bar

- Temperature range: -20 to 120 deg.C

- Elongation at break: 200%

- Color: White, Black

- Thickness: 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10 mm, 15mm, 20mm

- Width x Length : 1000 x 10.000 mm, 1200 x 10.000mm, or 1500 x 1500, 2000 x 2000mm

- Origin: China, Vietnam, India, Japan, Korea, EU

Technical Specification

- Petroleum: Good

- Lubricating Oils: Good

- Acid: Good

- Alkali: Fair

- Impermeable to Gases: Good

- Ozone & Weathering: Fair

- Oxidation: Good

- Water Resistance: Good

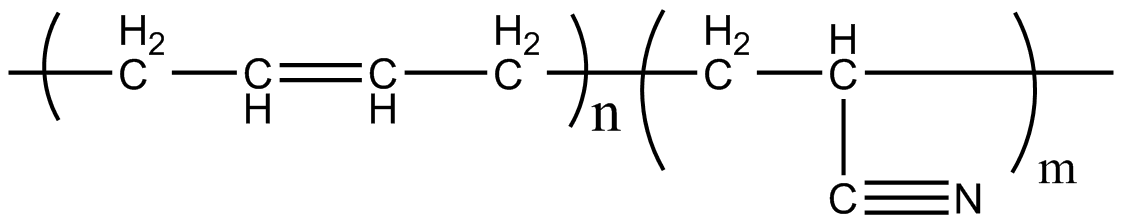

Structure of NBR Rubber

- NBR rubber structure is a copolymer of butadiene and acrylonitrile. NBR is produced by emulsion polymerization, the process of forming NBR rubber follows the following basic stages: Polymerize NBR in latex form, then coagulate and dry the latex. The Copolymerization process can be hot or cold polymerized to produce the final product.

- Normally, cold Copolymer products are softer and thinner than hot Copolymers. They are classified based on the acrylonitrile (ACN) ratio of the copolymer viscosity and the polymer chain

Different Type of NBR Rubbers

• NBR Rubber Sheet

• NBR Rubber Flange Gasket

- Nitrile rubber gaskets are cut from a NBR Rubber Sheet that provides excellent resistance to most petroleum based fluids, greases and oils.

• O-Rring NBR Rubber

• NBR Rubber Cord

• NBR Rubber Fabric Reinforced Sheet

Key Features of NBR Rubber

- Superior resistance to petroleum-based hydraulic fluids

- Very good resistance to oil and gasoline

- Very good resistance to alkalis and acids

- Good resistance to hydrocarbon solvents

- Wide range of service temperatures

- White FDA & 3A Sanitary Standards available

- Commonly used in the automotive sector.

- Highly resistant to petroleum, greases, oils and abrasion.

- Good tensile strength.

Applications of NBR Rubber

-

- NBR rubber is the most popular rubber in machine sealing parts.

-

- NBR oil-resistant rubber is used in gasoline, oil, kerosene, diesel, some acids and bases.

-

- NBR oil-resistant rubber gaskets are used as gaskets for pipe flanges and machine faces of industrial machinery and equipment...

-

- NBR oil-resistant Oring is the standard material for hydraulics and pneumatics.

-

- NBR rubber seals are used to seal oil and dust in machine parts.