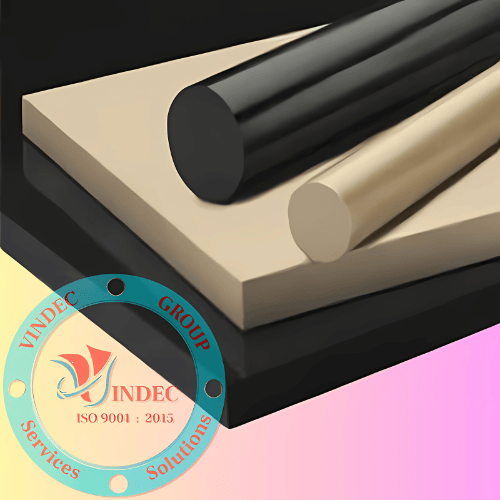

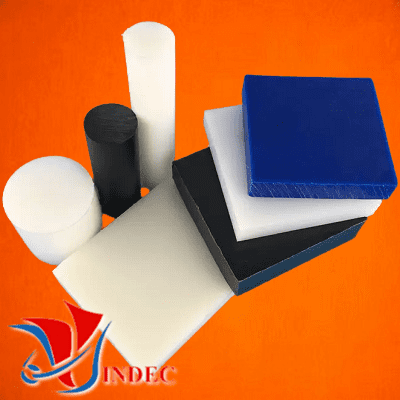

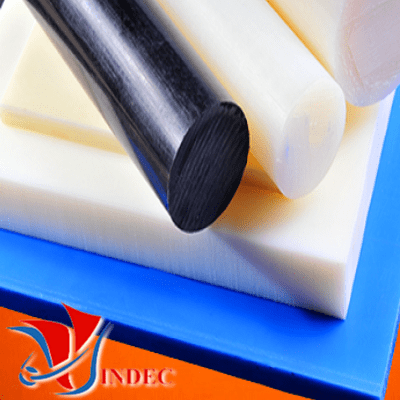

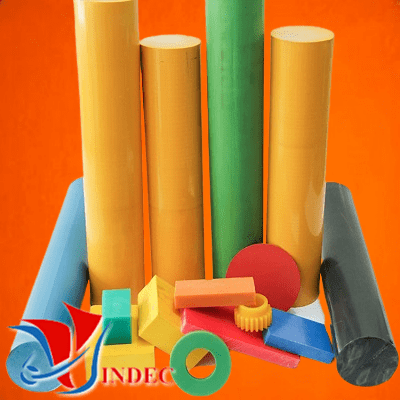

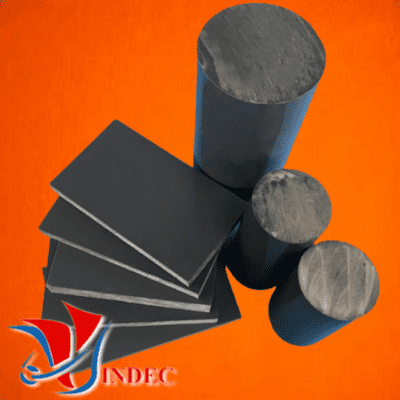

Plastic Products

What is Plastic?

Plastic is a general term that can be used to describe any synthetic material made from a wide range of organic polymers.

Different Type of Plastic

- Performance Plastic, Fluoro Plastic, General Plastic, Transparent Plastic, Phenolic & Bakelite Plastic

Performance Plastic

PEEK Plastic, PEI Plastic, PPS Plastic, PAI Plastic, PBI Plastic, PI Plastic

- PEEK Plastic

+ Poly ether ether ketone (PEEK) is a high performance semi-crystalline, engineering thermoplastic. PEEK is used in some of the toughest plastic applications that require the tightest tolerances.

- PEI Plastic

+ Polyetherimide (PEI) is an amorphous engineering thermoplastic. It is characterized by high heat resistance - CUT = 338°F (170°C), high strength and modulus, as well as excellent electrical insulating properties, which are stable over wide ranges of temperature and frequency and considered one of the most high performance plastics on the market.

- PPS Plastic

+ Polyphenylene sulfide (PPS) is an organic polymer consisting of aromatic rings linked by sulfides. Synthetic fiber and textiles derived from this polymer resist chemical and thermal attack. PPS is used in filter fabric for coal boilers, papermaking felts, electrical insulation, film capacitors, specialty membranes, gaskets, and packings.

- PAI Plastic

+ Polyamide-imides (PAI) are either thermosetting or thermoplastic, amorphous polymers that have exceptional mechanical, thermal and chemical resistant properties. Polyamide-imides are used extensively as wire coatings in making magnet wire.

- PBI Plastic

+ Polybenzimidazole (PBI) has exceptional thermal and chemical stability and does not readily ignite. Due to its high stability, polybenzimidazole is used to fabricate high-performance protective apparel such as firefighter’s gear, astronaut space suits, high temperature protective gloves, welders’ apparel and aircraft wall fabrics.

- PI Plastic

+ This a high-performance polyimide resin. performs well with or without lubrication under conditions which would destroy other plastics or severely wear many metals. PI parts function over a wide range of temperatures and stresses. retains its outstanding creep, abrasion resistance, and strength under adverse conditions.

Fluoro Plastic

PCTFE Plastic, CTFE Plastic, PFA Plastic, FEP Plastic, PVDF Plastic, ECTFE Plastic, PTFE Plastic, E-PTFE Plastic

- PCTFE Plastic

+ Polychlorotrifluorethylene (PCTFE or PTFCE) , is the homopolymer of chlorotrifluorethylene. PCTFE offers the unique combination of physical and mechanical properties, nonflammability, high optical transparency, chemical resistance, near zero moisture, and excellent electrical properties that cannot be found in other thermoplastic fluoropolymers.

- CTFE Plastic

Cholortrifluoroethylene: Excellent insulator, chemical and moisture resistant, low deformation, translucent in color.

- PFA Plastic

Perfluoroalkoxy alkane (PFA) are fluoropolymers with properties similar to polytetrafluoroethylene (PTFE) prepared polytetrafluoroethylene perfluoro methylvinylether, with a different ratio of PTFE and MVE monomers from PFA, is MFA.

- FEP Plastic

Fluorinated ethylene propylene or FEP is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the PTFE (polytetrafluoroethylene) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques.

- PVDF Plastic

Polyvinylidene fluoride, or polyvinylidene difluoride (PVDF) member of the fluoropolymer family. PVDF is a highly non-reactive thermoplastic fluoropolymer produced by the polymerization of vinylidene difluoride. PVDF is a specialty plastic used in applications requiring the highest purity, as well as resistance to solvents, acids and bases.

- ECTFE Plastic

ECTFE are proven performers in the chemical and petrochemical processing industries. Their unique combination of properties and design versatility are helping to solve some of the toughest materials problems in process equipment and components. ECTFE is a partially fluorinated semi-crystaline polymer offering a unique combination of mechanical properties, thermal and chemical resistance with outstanding ease of processability.

- PTFE Plastic

Virgin grade PTFE has advanced properties making it an ideal choice of material for a wide range of applications.Our beluns virgin grade of PTFE is available in rod, sheet, parts and tube. PTFE rod, PTFE shee, PTFE Partst and PTFE tube is particularly useful where high temperature or excellent chemical resistance is required.

- E-PTFE Plastic

+ Expanded PTFE (E-PTFE) Sheet Expanded PTFE Sheet made from biaxial oriented expanded PTFE sheeting that is laminated to the required thickness. Expanded 100% virgin PTFE using a proprietary process that products a uniform and highly frbrillated microstructure with equal tensile strength in all directions.

General Plastic

HDPE Plastic, PA (Nylon) Plastic, POM Plastic, UHMWPE Plastic, ABS Plastic, PP Plastic, PU Plastic

- HDPE Plastic

+ High Density Polyethylene (HDPE) is more rigid and harder than lower density materials. It also has higher tensile strength, four times that of low density polyethylene. It is three times better in compressive strength and meets FDA requirements for direct food contact applications.

- PA (Nylon) Plastic

Polyamides (Nylon / PA),These Polyamides, commonly referred to as nylon and available in Nylon Sheets, Nylon Rod and Nylon Tube and are distinguished by different types. The most common engineering nylons are PA6 and PA66. Nylon stock shapes are produced by either extrusion or casting.

- POM Plastic

Polyoxymethylene (POM), also known as Homo-Polymer acetal. VINDEC offers a wide selection of natural acetal plastic, black acetal sheet, as well as black and natural acetal rod at discount prices with no minumums.

- UHMWPE Plastic

+ Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) is a subset of the thermoplastic polyethylene. Also known as high-modulus polyethylene, (HMPE), or high-performance polyethylene (HPPE), it has extremely long chains, with a molecular mass usually between 3.5 and 7.5 million amu.

- ABS Plastic

+ Acrylonitrile-Butadine-Styrene (ABS) is a low cost engineering plastic that is easy to machine and fabricate. ABS is an ideal material for structural applications when impact resistance, strength, and stiffness are required.

- PP Plastic

Fluorinated ethylene propylene or FEP is a copolymer of hexafluoropropylene and tetrafluoroethylene. It differs from the PTFE (polytetrafluoroethylene) resins in that it is melt-processable using conventional injection molding and screw extrusion techniques.

- PU Plastic

+ Polyurethane (PUR and PU) is a polymer composed of organic units joined by carbamate (urethane) links. While most polyurethanes are thermosetting polymers that do not melt when heated, thermoplastic polyurethanes are also available.

Transparent Plastic

PMMA Plastic. PC Plastic

- PMMA Plastic

+ Polymethylmethacrylate (PMMA), also known as acrylic or acrylic glass. PMMA is an economical alternative to polycarbonate (PC) when extreme strength is not necessary. Additionally, PMMA does not contain the potentially harmful bisphenol-A subunits found in polycarbonate.

- PC Plastic

+ Polycarbonates (PC) are a group of thermoplastic polymers containing carbonate groups in their chemical structures. Polycarbonates used in engineering are strong, tough materials, and some grades are optically transparent.

Phenolic & Bakelite Plastic

- Phenolics Plastic

+ Bakelite Phenolic: Phenolic paper is a material often used to make printed circuit board substrates (the flat board to which the components and traces are attached). Phenolic Cotton: natural color is typically light tan to brown. These grades are composed of a continuous cotton woven cloth impregnated with a phenolic resin binder.

Applications of Plastic Products

Choose an Industry to filter all of our materials below.

- Application for Aerospace : Virgin PTFE, Glass Moly, Porous PTFE, PCTFE, PEEK, PPS, PEI.

- Application for Commercial Products: Glass Fiber, UHMW-PE

- Application for Cryogenic: PCTFE

- Application for Defense: ETFE

- Application for Energy: Carbon Fiber Filled PTFE, Glass Fiber Filled PTFE, Bronze PTFE Filled PTFE

- Application for Food: PFA, FEP, ETFE, PEEK, UHMWPE

- Application for Hydraulics: Bronze PTFE

- Application for Industrial: Carbon Filled, Carbon Graphite, Glass Moly, Graphite. Aromatic Polyester Fille PTFE, Polyimide-Filled PTFE, Modified PTFE, Porous PTFE, PerFluoro Alkoxy (PFA), Poly CloroTri Fluoro Ethylene (PCTFE), Ethylene Tetra Fluoro Ethylenes (ETFE), Ultra-High Molecular Weight Poly Ethylenes (UHMWPE)

- Application for Laser: Poly Vinyli Dene Fluoride (PVDF)

- Application for Mechanical: Carbon Filled PTFE, Carbon Graphite Filled PTFE, Glass Fiber Filled PTFE, Graphite Filled PTFE, Bronze Filled PTFE, UHMWPE

- Application for Medical: FEP, PCTFE, ETFE, PEEK, PEI

- Application for Nuclear: PCTFE, ETFE

- Application for Oil And Gas: Virgin PTFE, Carbon Filled PTFE, Carbon Graphite Filled PTFE, Glass Moly Filled PTFE, Glass Fiber Filled PTFE, Graphite Filled PTFE, Bronze PTFE, Modified PTFE, PFA, FEP, PVDF, PCTFE, ETFE, PEEK, UHMWPE, PPS

- Application for Sealing: Virgin PTFE, Carbon Fiber Filled PTFE, Aromatic Polyester Fille PTFE, Polyimide Filled PTFE, PEEK

- Application for Semiconductor: Virgin PTFE, Modified PTFE, PFA, PVDF, PEEK, PPS, PEI